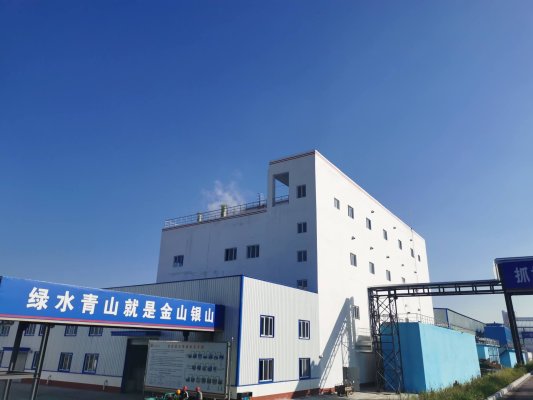

About the project

Located in northwest China, this project engages in coking wastewater treatment, realizing valuable salt production & ZLD.

With a raw wastewater membrane concentration treatment capacity of 130 m3/h, followed by the evaporation treatment capacity of 14 m3/h NaCl and 11 m3/h Na2SO4, this project is controlled via a center control room, involving the following systems:

Salt Production

i. NaCl triple-effect evaporation crystallization

ii. Na2SO4 double-effect evaporation crystallization

iii. Na2SO4 freezing crystallization

iv. Na2SO4 single-effect recrystallization

ZLD

v. Mix Salt Single-effect evaporation crystallization

Salt Production

It takes 4 unique processes to acquire industrial-grade Na2SO4 & NaCl salt separately.

i. NaCl production (Triple-effect evaporation crystallization)

As the raw wastewater bears a higher NaCl content than Na2SO4, the NaCl extraction by evaporation first serves the most common adoption:

-

- The preheaters are adopted to make the best usage of the heat from condensate & secondary steam.

- To concentrate the wastewater, the 1st& 2nd effect falling film evaporators operate with the assistance of gravity, and the secondary steam from the separators enters the following effect evaporator.

- With a high circulation speed, the slurry is heated in the 3rd effect forced circulation evaporator. The NaCl salt will form in the crystallizer within a certain temperature range.

- With the treatment of the thickener and centrifuge, the NaCl salt is separated from the slurry.

- The boiling fluidized bed dryer, followed by a buffer tank and a packing unit, drys the discharge NaCl salt and packed with ton bags.

ii. Na2SO4 slurry concentration (Double-effect evaporation concentration)

With the crystallization of NaCl salt from the slurry, the remaining wastewater contains a relatively high content of Na2SO4. However, to extract the Na2SO4 by freezing crystallization, a higher content of Na2SO4 is required:

-

- Heated through the preheaters and 1steffect falling film evaporator, the slurry steps into the 2nd effect forced circulation evaporator, with its secondary steam adopted as the heating medium for the 2nd effect forced circulation evaporator.

- After the double-effect evaporation treatment, the dehydrated slurry will be discharged into the freezing crystallization feeding tank for further processing.

iii. Na2SO4·10H2O extraction (Freezing crystallization)

The freezing crystallization process plays a vital role in the purpose of salt separation, realizing high-purity Na2SO4 salt extraction.

-

- To reach a certain low temperature for crystallization, the concentrated slurry is treated by the precooler & forced circulation cooler in an order.

- In the crystallizer, the Na2SO4·10H2O forms.

- Then, the crystal salt is treated with a thickener and centrifuge.

- The hot melt tank collects the centrifuged crystal salt for further processing.

iv. Na2SO4 extraction (Single effect recrystallization)

Then, to extract high-purity Na2SO4, recrystallization is introduced:

-

- In the single-effect forced circulation system, the Na2SO4•10H2O crystal is heated and re-dissolved with saturation Na2SO4 solution from the dosing unit.

- In the crystallizer, the Na2SO4 crystal precipitates.

- Then, the Na2SO4 crystal is separated with the slurry, through a thickener and centrifuge.

- What follows is the dehydration of the Na2SO4 crystal via a boiling fluidized bed dryer, acquiring the high-purity Na2SO4 salt packed in ton bags via a packing unit.

ZLD

v. Mix salt discharge (Single-effect evaporation crystallization)

The dehydration of the remaining mother liquor from the processes before discharge realizes:

-

- ZLD

- operation cost reduction

-

- The buffer tanks collect the remaining mother liquor from the previous processes.

- The slurry will be heated by the preheaters and single effect forced circulation evaporator in a row.

- The mixed salt precipitates in the separator.

- Through a centrifuge and a drum dryer, the dehydrated mix salt can be discharged directly.

About Sanfeng Tech

Sanfeng Tech vigorously engages in providing wastewater treatment solutions by providing our client with a combination of processes involving:

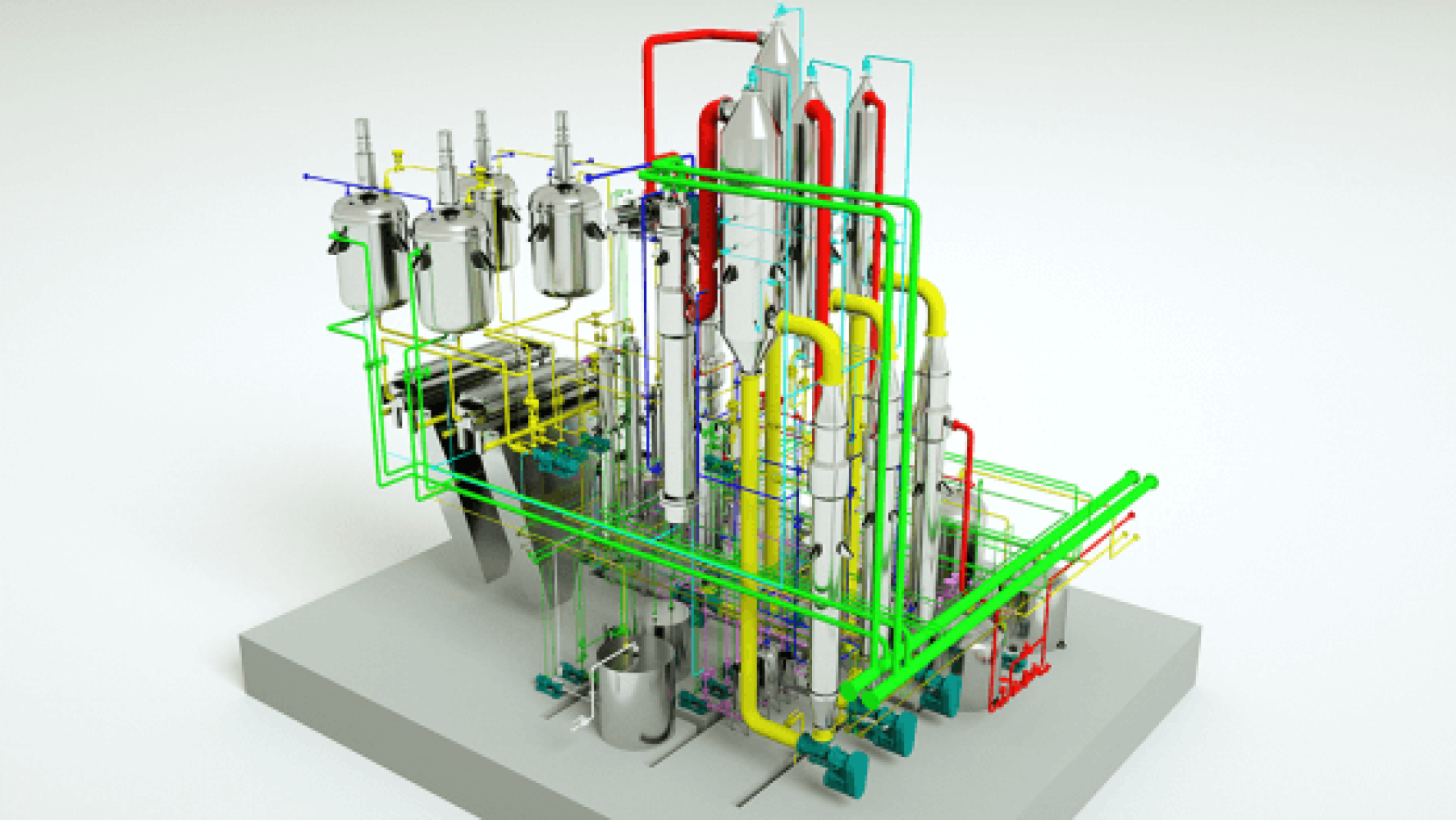

Our experienced 3D design and turn-key project delivery serve our client’s best interests, in different fields, such as:

-

- hazardous waste industry,

- petrochemicals industry

- mine industry

- etc.