- Source of coal chemical industry wastewater

Process wastewater:

- Coal gasification wastewater: it containsa large amount of organic matter, ammonia nitrogen, inorganic salt and suspended solids.

- Process unit wastewater

- Desulfurization wastewater

High saltwastewater:

It mainly comes from the circulating water system, the desalting water system and the process wastewater after biochemical treatment, which usually has large hardness, high salinity and contains a small amount of organic matter.

- Mainstream treatment technologies in coal chemical industry

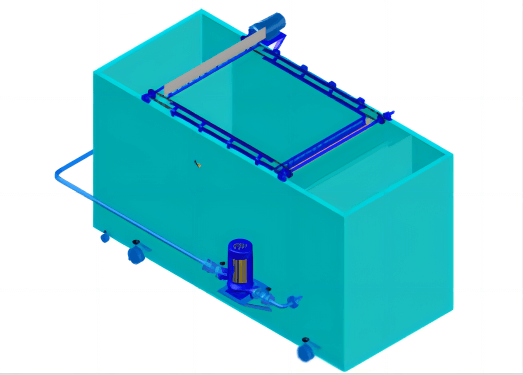

- Air flotation technology

Air flotation technology is widely used in wastewater treatment, it can effectively remove the floating catkins, using highly dispersed tiny bubbles as carrier adhesion to the suspended pollutants in wastewater, to make its buoyancy is greater than gravity and resistance, so that the pollutants rise to the surface, forming foam, and then scraping the foam from the surface, which can realize the process of solid-liquid or liquid separation.

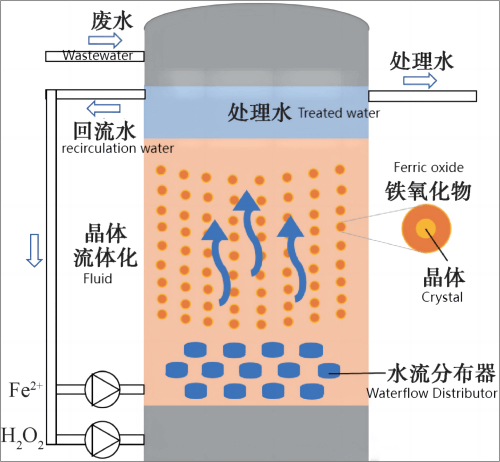

- Fenton oxidation method

Fenton oxidation method is under acidic conditions, its H₂O₂ in the presence of Fe² + to generate a strong oxidation capacity of OH¯, and trigger more other reactive oxygen species, to achieve the degradation of organic matter, its oxidation process is chain reaction. OH¯ production is the beginning of the chain, while other reactive oxygen species and reaction intermediates constitute the nodes of the chain, each reactive oxygen species is consumed and the reaction chain ends. The reaction mechanism is more complex, and these reactive oxygen species only supply organic molecules and convert them into inorganic substances such as CO₂ and H₂O, thus making Fenton oxidation one of the important advanced oxidation technologies.

- Biochemicaltechnology

In the coal chemical wastewater treatment, biochemical technology is the core technology, only by ensuring that the preliminary design is scientific and reasonable, can the water meet the standard discharge requirements. Biochemical system focuses on removing ammonia nitrogen, because the ammonia nitrogen in the water is relatively high, and two-stage A/O is used to improve COD removal and nitration.

- Ultrafiltration

Ultrafiltration is a physical process for separation, purification and concentration of the materials in the liquid under certain pressure. It can remove impurities such as suspended solids, colloids, turbidity, organic matter and bacteria. At present, ultrafiltration membrane technology has been used in seawater desalination, water reuse, pretreatment of RO system, condensate water treatment and preparation of ultrapure water.

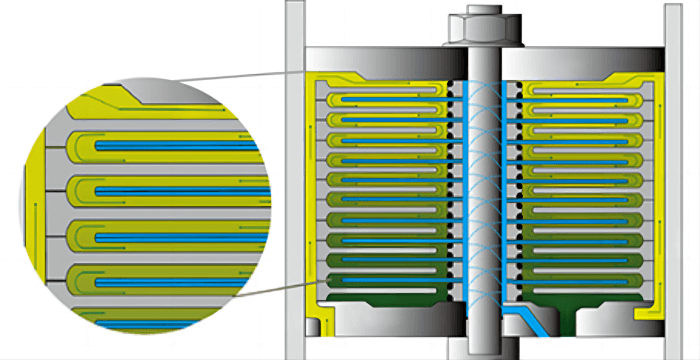

- Reverse osmosis

Disc tube reverse osmosis(DTRO) is one kind of reverse osmosis, specially used to treat high concentration of wastewater, and its core technology is disc tube membrane column. The reverse osmosis membrane and the hydraulic diversion disk are placed together, fixed with the central pull rod and the end plate, and then placed into the pressure-resistant sleeve to form a membrane column. DTRO overcomes the disadvantage that the general reverse osmosis system is easy to block when handling the leachate, which makes the system more stable and has lower operation cost.

- Evaporation Crystallization

After the membrane concentration process, the salt of the concentrated water reaches 6% -12%, and the water volume is reduced. In order to meet the zero liquid discharge requirement, the concentrate needs to be further treated. The two methods are often adopted: one is evaporation pond method; the other is thermal evaporation crystallization method, which covers a small area, and can effectively control the crystallized salt, so it is widely used in the ZLD treatment of coal chemical wastewater.

The existing thermal evaporation crystallization process can be divided into two types, namely MVR evaporation process and multi-effect evaporation process. The salt produced by the thermal crystallization process belongs to hazardous waste, and the transportation cost is relatively high. In order to reduce the economic pressure, the parameters of the evaporation crystallization unit can be flexibly adjusted, so that the treated salt can meet the requirements of product level.

- Typical cases in Sanfeng

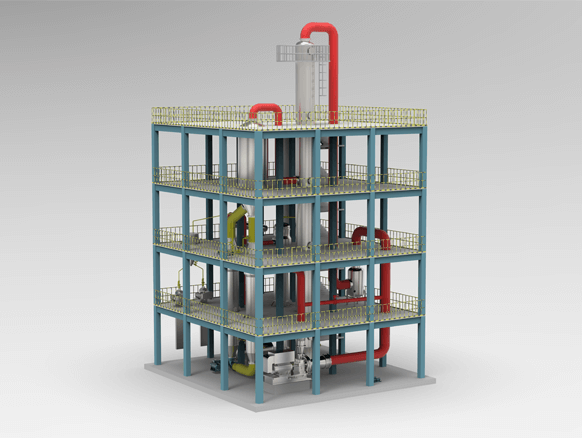

Take the following project by our company for example: From the 3D diagram, it shows the process of sodium sulfate/ sodium chloride multi-effect, freezing crystallization and the drying system.

Zero liquid discharge of coal chemical wastewater is a special requirement for the development of the industry, and also the technical support for low-carbon, high efficient and sustainable development. With the improvement of wastewater recycling and discharge requirements, the zero liquid discharge system with crystallization as the core will become the mainstream of coal chemical wastewater treatment.

In the future, we Sanfeng will further improve efficiency, reduce energy consumption and save cost, and continue to develop towards the goal of qualitative treatment and resource recovery of high-salt wastewater. For more solutions about the wastewater, welcome to our website and feel free to contact us!