I. Why the high-salinity effluent stand as a challenge in ecodevelopment?

High-salinity effluent compounds, such as more than 1% of the salt mass fraction, more than 3.5% total dissolved solids (TDS), solvable inorganic ions (such as Cl–, SO42-, Na+, Ca2+, etc), and unmanageable organic pollutant, all stand in the way of Salt extraction and zero liquid discharge(ZLD).

In the disposal of these hazardous elements and recovery of useful resources, heavy investment haunts the enterprises for a long time.

However, with constantly improving technologies, the goal of such ecodevelopment has been fulfilled practicably and economically through the combination of proven concentration and crystallization technologies.

II. How to realize the resource recovery & ZLD?

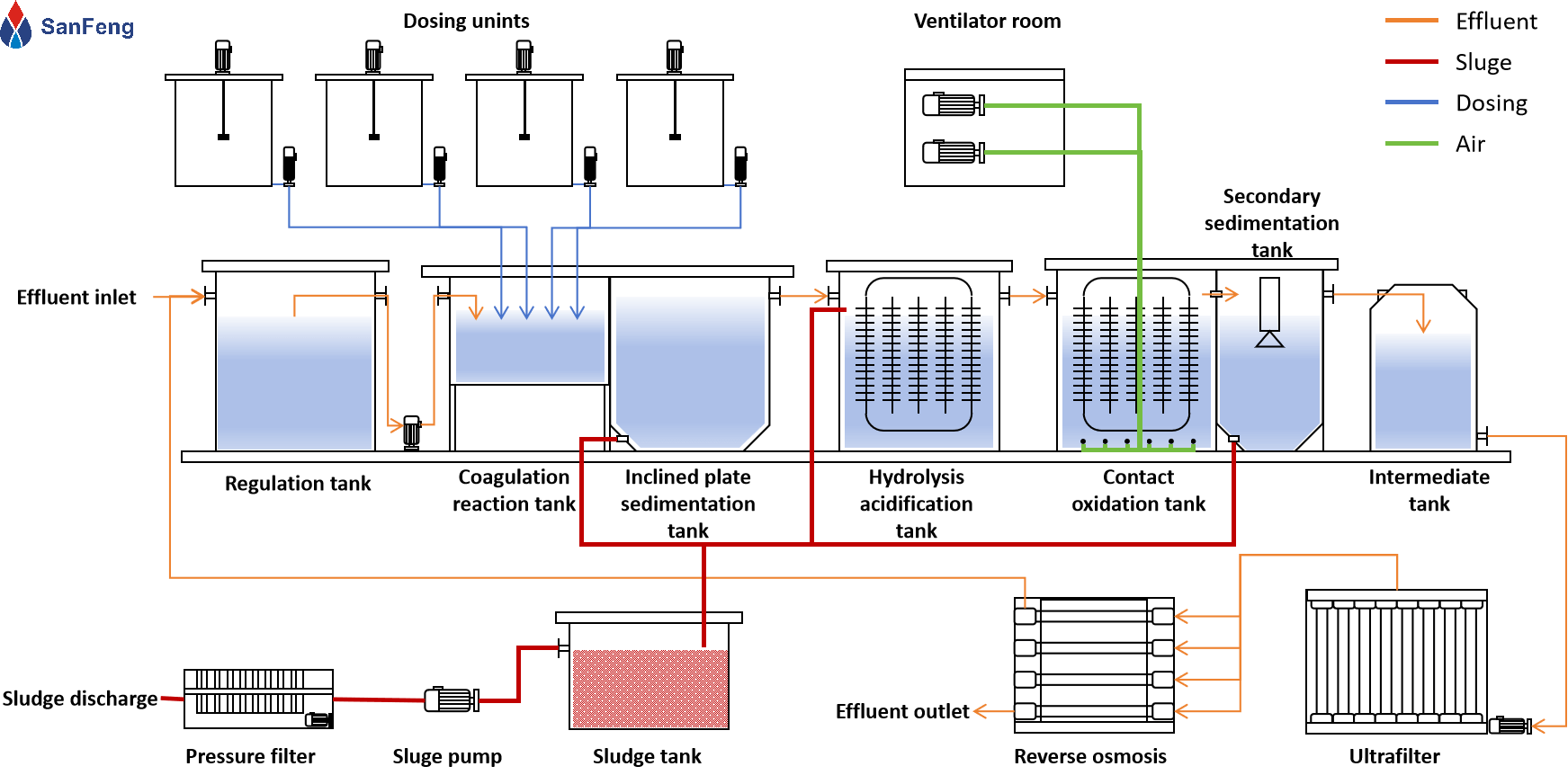

Phase 1 Pretreatment

To remove the elements that will impact the contraction and crystallization process, according to the different features of the high-salt effluents, methods, such as chemical precipitation, multi-medium filtration, ion-exchange resin, adsorption, etc, will be carried out for the preparation of the following procedure of concentration and crystallization.

Phase 2 Concentration

Concentration serves the purpose of reducing the effluent volume to improve the efficiency of the evaporation crystallization. According to different application targets and adoption scopes, contraction technologies can be divided into:

- Membrane concentration

- Thermal concentration

- Membrane concentration

- Driven by the difference in pressure, concentration, and potential, utilizing the size difference between the compound and membrane, charge repulsion, and physicochemical interaction, it realizes the separation, purification, and concentration of the effluent. Major membrane concentration methods involve:

- Microfiltration (MF)

- Ultrafiltration (UF)

- Nanofiltration (NF)

- Reverse osmosis (RO)

- Electrodialysis (ED)

- Membrane distillation (MD)

- Driven by the difference in pressure, concentration, and potential, utilizing the size difference between the compound and membrane, charge repulsion, and physicochemical interaction, it realizes the separation, purification, and concentration of the effluent. Major membrane concentration methods involve:

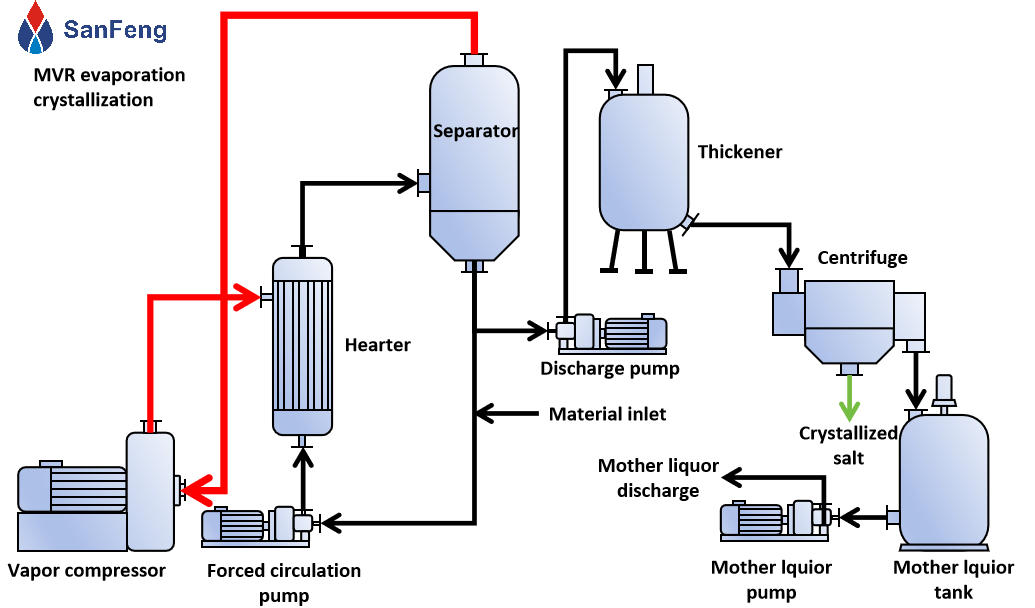

- Thermal concentration

- Mostly adopted to process the effluent featuring high TDS and COD, it operates by heating the high-salinity effluent. Such technologies majorly involve:

- Multistage flash evaporation (MSF),

- Multi-effect evaporation (MEE),

- Mechanical vapor recompression (MVR).

- Mostly adopted to process the effluent featuring high TDS and COD, it operates by heating the high-salinity effluent. Such technologies majorly involve:

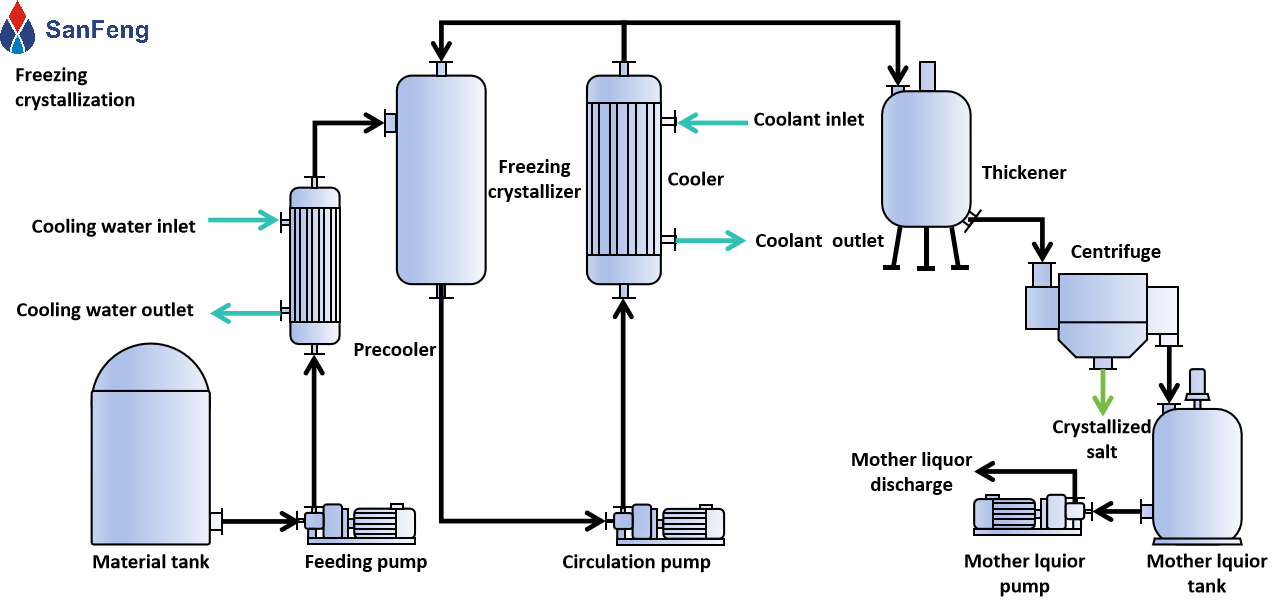

Phase 3 Crystallization

Crystallization technologies play the last vital process in high-salinity effluent treatment, regarded as the core element for the realization of liquid-solid separation.

Nowadays, compared with traditional evaporation crystallization, the widely adopted salt-separation crystallization results in better water utilization and recovery of industrial-grade salt.

Such technology earns an application prospect, regarded as the development direction of the effluent treatment in the future.

III. Live project case

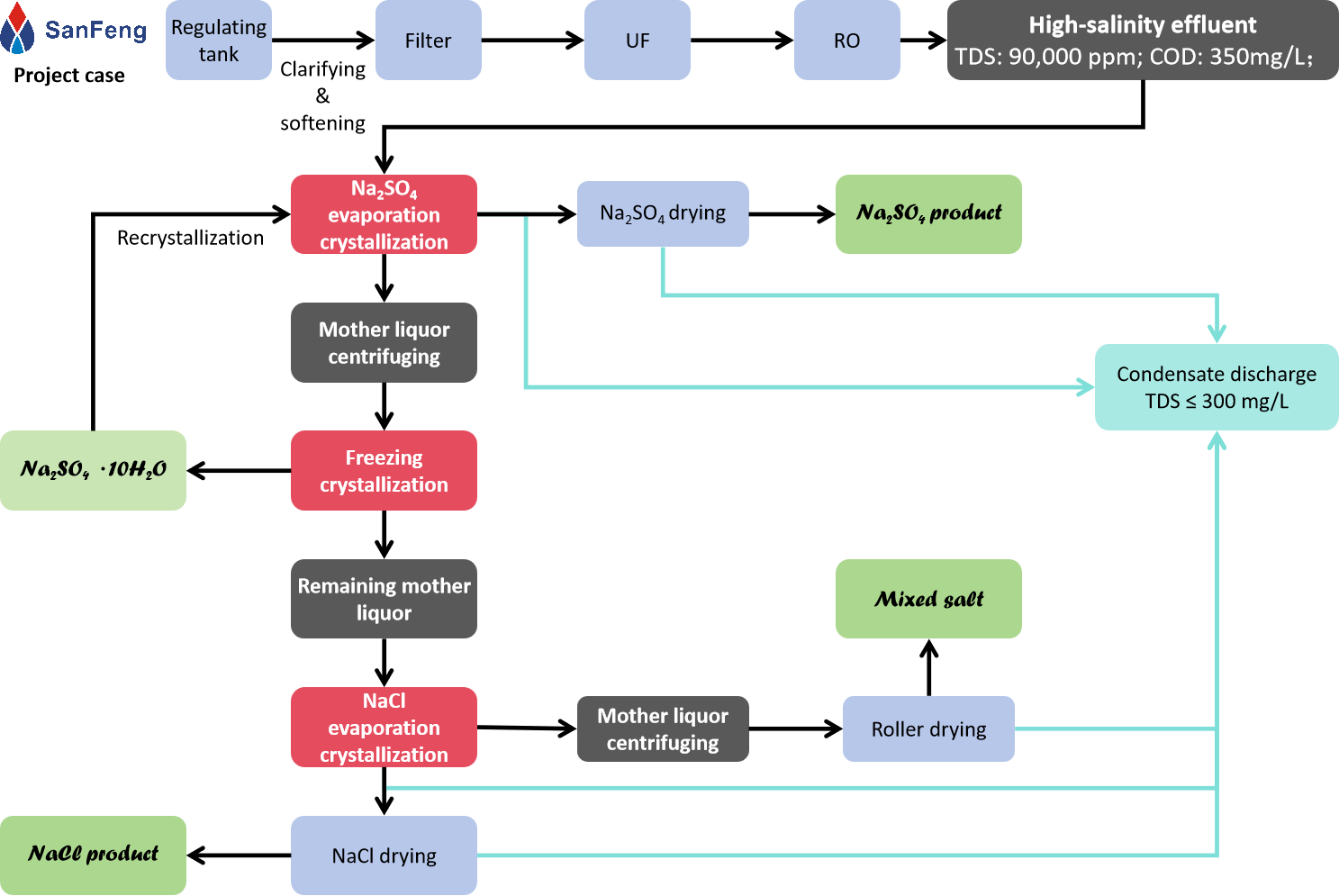

Following the pretreatment, Sanfeng Tech presents its professional effects in the process of salt-separation crystallization.

The feed:

Na2SO4 & NaCl (TDS: 90,000 ppm; COD: 350mg/L)

The process:

- Na2SO4 extraction & purification:

- Extract Na2SO4 via evaporation crystallization

- Na2SO4 ·10H2O crystallization via freezing crystallization

- Na2SO4 purification via recrystallization and evaporation crystallization

- Product salt drying & packing

- NaCl extraction:

- From the remaining centrifuged mother liquor, extract the NaCl via evaporation crystallization

- Product salt drying & packing

- Discharge of mixed salt & condensate:

- Mixed salt extraction & packing via centrifuged mother liquor drying.

- Condensate collection & discharge from evaporation & drying system.

The products:

- Industrial-grade Na2SO4

- Industrial-grade NaCl

- Mixed salt

- Condensate (TDS ≤ 300 mg/L).

Thanks to the successful valuable salt recovery, the harmless remains solid, and condensate (TDS ≤ 300 mg/L) can be discharged without any environmental negative effect.

IV. Why choose Sanfeng Tech?

Following a standardized execution procedure, Sanfeng Tech services our clients‘ best interests.

- Solution analysis.

- Elements will be taken into consideration comprehensively for the analysis of the proper solution issuance. Such as:

- The water quality,

- Salt-separation technology,

- The security of the investment management,

- The project site’s surrounding environment.

- Elements will be taken into consideration comprehensively for the analysis of the proper solution issuance. Such as:

- Process design.

- Based on the analysis, Sanfeng Tech is able to provide multiple technical approaches to realize salt extraction & ZLD, such as:

- The combination of thermal (MVR/MEE) evaporation concentration, freezing crystallization, and melt crystallization;

- The combination of thermal (MVR/MEE) evaporation crystallization, freezing crystallization, and melt crystallization.

- Based on the analysis, Sanfeng Tech is able to provide multiple technical approaches to realize salt extraction & ZLD, such as:

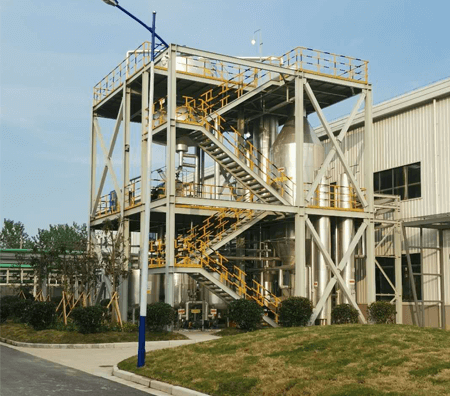

3. Equipment Manufacture.

The following effects guarantee our equipment’s quality

-

- Cutting-edge manufacturing equipment

- Experienced manufacturing specialists

- Strict quality management control

4. On-site installation instruction.

-

- Our project manager’s patience and full support ensure the successful installation of the whole facility.

5. Commissioning & operation training.

Our experts with an abundance of experience will assist you in:

-

- System commissioning

- Operation training with an operating manual

- After-sale service

By involving massive resources and reserved technologies, Sanfeng Tech specializes in the treatment process of salt-separation and the evaporation treatment of high-salinity and DOC effluent, such as the wastewater of NaCl, Na2SO4, (NH4)2SO2, NH4Cl, KCl, etc.