Zero Liquid Discharge

What is Zero Liquid Discharge(ZLD)?

Definition:

ZLD is short for Zero Liquid Discharge, is a treatment process to recover the water from the solution and concentrate the solid for disposal or resourced material.

ZLD technology:

Now the application in the effluent treatment of ZLD is to reduce the wastewater and produce clean water for reuse, meanwhile, it also recovers valuable resources from the wastewater, like NaCl, Na₂SO₄, which can be sold or reused in the industrial process, to treat the industrial wastewater.

ZLD for brine treatment:

- Brine pre-concentration

- Evaporation/crystallization process

Turn the brine into highly purified water and solid product for disposal or for salt recovery. Increasingly strictly brine wastewater discharge regulations have profoundly affected the necessity of ZLD, especially when water resources are scarce and a large amount of municipal and industrial wastewater is wasted.

Why ZLD for industrial wastewater treatment?

- Meeting stricter environmental regulations

- Reducing the pollution and damage to the local environment and ecology

- Relieving the problem of water shortage

- Reducing the volume of wastewater discharged from the plant

- Recycling the wastewater

- Reducing waste disposal management costs

- Recovering valuable solid salt

- Reducing the operating cost with the MVR system

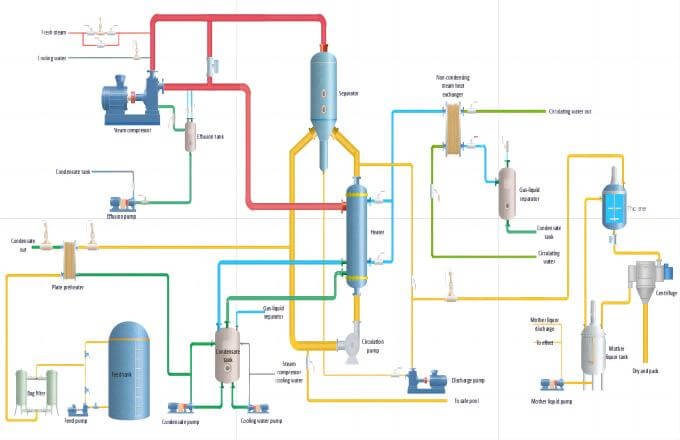

ZLD Design Process in industrial wastewater treatment

The most commonly system in the ZLD processes consist of the pre-concentration and thermal evaporator/crystallizer systems.

Pre-concentration

- Pre-concentration always be done with the membrane-based technology, has been incorporated into ZLD systems to improve energy and cost efficiencies.

- After the pre-concentration concentrate

- The salinity up to 6~8%

- Recover 70% water

Thermal Evaporation and Crystallization (Separation) System

- After the Evaporator and crystallizer system

- recover the 95~98% water.

- the solution concentration up to 45~55%.

Liquid-solid Separation System /Drying system

- To separate or dry the solution.

What ZLD process can Sanfeng offer?

Sanfeng offer the ZLD system with thermal evaporation technology integrate with pretreatment and drying technology to treat RO reject water or Brine wastewater.

Evaporation Crystallization technology

- Hardness removal

- F- removal

- SS removal

Drying System

- 6~10% moisture drying system

- 5% moisture drying system

- less than 5% moisture drying system

The Special Engineering Design in Sanfeng Tech

Steam compressor manufacturer

Sanfeng Tech brings the start-of-art technology, depth experience, and applications knowledge to industries, with 63 years of designing, production, and upgrading advanced manufacturer facility, including the mechanical vapor compressor solutions for any MVR Evaporator or Crystallizer application for Water Reuse, Concentration, Separation, Zero Liquid Discharge (ZLD), etc.

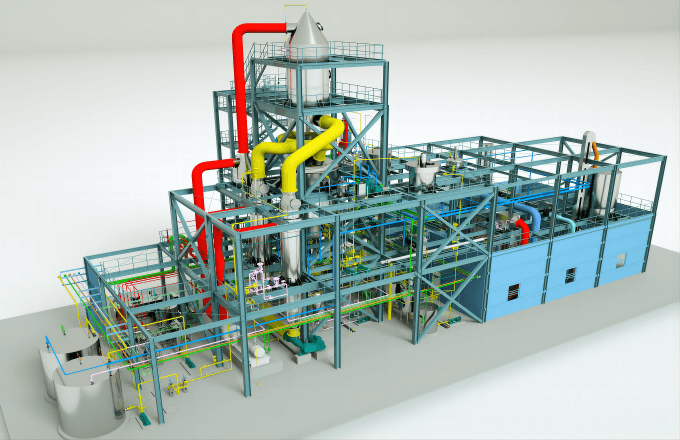

Clearly 3D drawings

For corrective and effective design

For the installation and commissioning supervision

Redesigned and Customized Automative Control System