NCM Battery Production

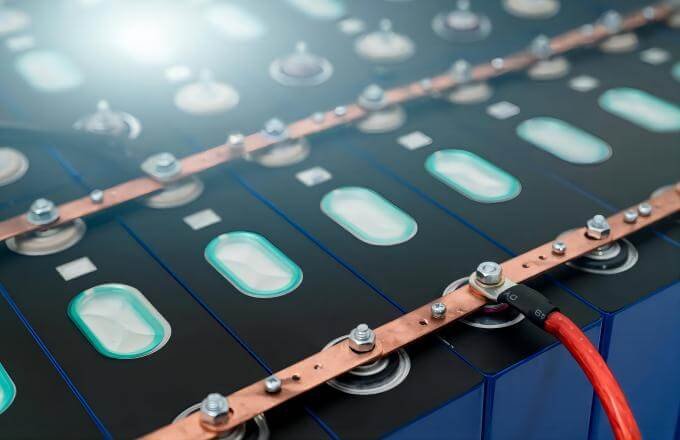

Ternary lithium/ NCM battery

Ternary lithium/ NCM battery refers to the lithium battery that uses the three transitional metal oxides, nickel, cobalt, manganese as anode materials. Because of its advantages of relatively safety, high capacity, long cycle life and low cost, it has become the product that has the most promising research prospect and production application.

In the production of ternary lithium battery, the wastewater is characterized by uneven discharge, complex composition, high salinity, high content of heavy metal ions, strong acid and alkalinity and poor biochemistry, and the wastewater not effectively treated will cause adverse effects on human health and ecological security. At the same time, the ternary materials, metal foil, diaphragm, graphite, salt and other solid particles in the wastewater have great value of recycling.

ZLD Process - ternary lithium/ NCM battery production

Nickel-cobalt-manganese ternary anode material is one of the most popular ternary lithium battery materials. The wastewater of ternary lithium battery can be treated by classification to reduce the volume flowing into the evaporation crystallization system. At the same time, some impurities can be removed through pretreatment to facilitate the operation of the evaporation crystallization system. The special pretreatment for nickel-cobalt-manganese ternary precursor mainly include sulfide precipitation, ammonia removal from magnesium ammonium phosphate, decomplexation and distillation.

- Sulfide precipitation is a method of adding sodium sulfide or potassium sulfide, generating precipitation after reaction and removing heavy metal ions in lithium wastewater by filtration and separation.

Evaporation crystallization system:

Evaporation and crystallization system is an important link to realize the zero discharge of lithium battery wastewater, which has an important influence on whether the zero discharge can be realized. The evaporation crystallization system is mainly composed of evaporation chamber, evaporator, preheater, separator, condensate tank, crystallization heater, crystallization separator, steam compressor, secondary compressor, etc..

The process mainly includes multi-effect evaporation technology, MVR technology and flash technology. Among them, MVR technology compresses the secondary steam through the compressor, increases the pressure and saturation temperature, directly uses it as heat to replace fresh steam, at the same time without cooling treatment, the operation cost is relatively low.

When the wastewater is less and the content of recyclable materials is higher, the operating cost and return of zero discharge technology have strong advantages compared with the standard discharge of traditional lithium battery wastewater. Generally speaking, if the concentration of wastewater is low, the membrane treatment can be conducted first, after concentrated go into the evaporation crystallization system for treatment.

If all the excessive domestic sewage and the cleaning wastewater with low concentration adopt the zero discharge process based on evaporation, the cost is too high. In practice, the lithium cleaning wastewater after coagulation and precipitation is often mixed with the domestic sewage of the plant area and then go into the biochemical treatment system, which improves the biochemistry of the wastewater, and the effluent can be discharged up to standard.

Recycling process

- High-temperature calcinationprocess

Fire metallurgy process is simple and easy for industrialization, but organics such as electrolyte, will produce harmful gases under high-temperature calcination, which needs to be treated, so the disadvantages of this method are high energy consumption and high cost.

- Hydro-metallurgy process

Hydro-metallurgy is a very mature process, which can be used alone or combined with other processes. It has the advantages of low cost and low requirements of equipment, but has the disadvantages such as incomplete recycling of waste batteries and long process of treatment.