Lithium battery production

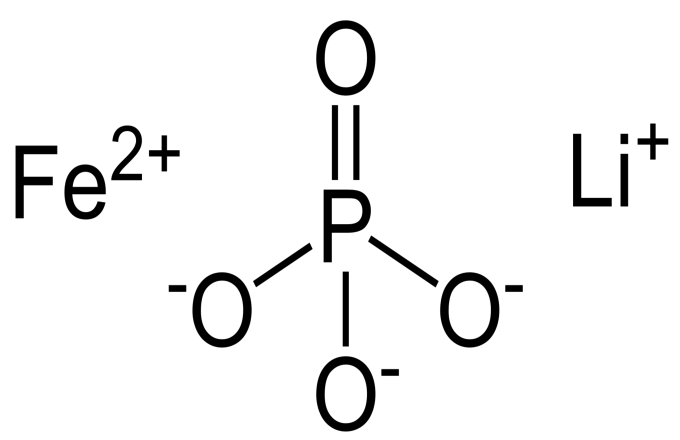

I. LFP Battery Production

Lithium iron phosphate production wastewater has a large volume, mainly containing high concentration of ammonia nitrogen, sulfate, phosphate, hardness ions. The organic content in the wastewater is low, and most of them are inorganic ions. How to realize its resource recovery has become a difficult problem in the industry.

Traditional process VS Sanfeng’s treatment process:

- Traditional wastewater treatment process:

It only recovers some of the components of the wastewater, such as recycling sulfate for preparation of calcium sulfate, and recycling ammonia nitrogen for ammonium salt or ammonia water, which makes the wastewater not fully treated; or through simple pretreatment, the wastewater is evaporated and crytallized to obtain the mixed salt of ammonium sulfate and ammonium phosphate, the impurities cannot be used. In addition, the traditional process is complex, high investment and operation cost, which does not conform to the development of energy conservation, environmental protection and circular economy.

- Treatment process in Sanfeng Tech:

Referring to engineering experience of mine water project, our company consider to combine membrane process with evaporation crystallization, and adopt the process of “classification collection + pretreatment + membrane + evaporation crystallization” to treat lithium iron phosphate wastewater. Collect the low concentrated water and high concentrated water separately, after purification, the low concentrated water is desalinated and concentrated through reverse osmosis, and the membrane filter liquid is to mixed with the

high concentrated water for evaporation crystallization, to recycle ammonium sulfate crystal, and realize resource recovery.The pretreatment, membrane concentration and evaporation are combined to convert the lithium iron phosphate production wastewater into recycling water, calcium phosphate, ammonium sulfate and ammonium phosphate, which realizes the “zero discharge” treatment and full quantification and low energy consumption of resource recovery. The combined process has good treatment effect and low investment and operation cost.

The waste LiFePO4 battery will firstly be discharged and dismantled, the battery shell, cathode material, anode material and diaphragm are dismantled and separated, and then recycled respectively. Among them, the anode material through heat treatment, alkali immersion or organic solvent method to separate the active substance, and then adopt high-temperature regeneration or wet process to recover the valuable metal.

The recovery and regeneration process of waste lithium iron phosphate anode material can be divided into high-temperature regeneration and wet process.

High-temperature regeneration method refers to high-temperature treatment after adding the corresponding element, which plays a repair role by supplementing the elements, and then improves the electrochemical performance of the recycled materials. Remove the impurities of the waste lithium iron phosphate, then add appropriate iron, lithium or phosphorus compounds. The mole ratio of iron, lithium and phosphorus is adjusted to a certain proportion, and finally the carbon is added for calcination.

The typical process mainly includes the following steps:

- Disassemble, break, and separate the cathode to obtain the waste lithium iron phosphate anode material;

- Dissolve aluminum foil by alkali melting method and separate waste LiFePO4;

- Use H2SO4 or HNO3 and H2O2 for acid immersion, and leach LiFePO4 residue;

- NaOH and NH3 H2O for chemical precipitation to obtain Fe (OH) 3;

- Use saturated Na2CO3 as the lithium precipitant, the lithium solution is separated from the residual solution after precipitation to obtain Li2CO3.

The results show that the leaching rate of lithium obtained by H2SO4 method and HNO3 method is more than 80%, and the aluminum hydroxide prepared can be recycled, and the purity of Li2CO3 recovered by hydrothermal precipitation can meet the battery level requirements, which is conducive to the realization of industrialization. However, the purity of lithium salt from this process is difficult to control, and it has high requirement for the corrosion resistance of equipment. The aluminum, copper, iron metals will be synchronous leaching, to get qualified lithium carbonate products, need to realize synchronous removal of the above metals, the difficulty will lead to higher recovery costs.

(1) High-temperature regeneration technology:

- Simple and short process, less material consumption and low pollution to the environment,

- Higher energy consumption, and the pretreatment requirements for waste materials are strict, removal of impurities is a must to avoid residue, which will affect the electrochemical performance of synthetic materials.

(2) Wet leaching technology:

It is relatively mature, and the pretreatment requirements for waste batteries are relatively low, which can achieve high metal recovery rate, so as to get high purity materials, and the equipment and technology are easy to achieve industrialization.

(3) biological recycling technology:

- Environmentally friendly, low requirements for equipment,

- The technology is not mature, the cost is high, the leaching conditions are difficult to control, and the large-scale industrialization is difficult to realize.

II. NCM Battery Production

Ternary lithium/ NCM battery refers to the lithium battery that uses the three transitional metal oxides, nickel, cobalt, manganese as anode materials. Because of its advantages of relatively safety, high capacity, long cycle life and low cost, it has become the product that has the most promising research prospect and production application.

In the production of ternary lithium battery, the wastewater is characterized by uneven discharge, complex composition, high salinity, high content of heavy metal ions, strong acid and alkalinity and poor biochemistry, and the wastewater not effectively treated will cause adverse effects on human health and ecological security. At the same time, the ternary materials, metal foil, diaphragm, graphite, salt and other solid particles in the wastewater have great value of recycling.

Nickel-cobalt-manganese ternary anode material is one of the most popular ternary lithium battery materials. The wastewater of ternary lithium battery can be treated by classification to reduce the volume flowing into the evaporation crystallization system. At the same time, some impurities can be removed through pretreatment to facilitate the operation of the evaporation crystallization system. The special pretreatment for nickel-cobalt-manganese ternary precursor mainly include sulfide precipitation, ammonia removal from magnesium ammonium phosphate, decomplexation and distillation.

- Sulfide precipitation is a method of adding sodium sulfide or potassium sulfide, generating precipitation after reaction and removing heavy metal ions in lithium wastewater by filtration and separation.

Evaporation crystallization system:

Evaporation and crystallization system is an important link to realize the zero discharge of lithium battery wastewater, which has an important influence on whether the zero discharge can be realized. The evaporation crystallization system is mainly composed of evaporation chamber, evaporator, preheater, separator, condensate tank, crystallization heater, crystallization separator, steam compressor, secondary compressor, etc..

The process mainly includes multi-effect evaporation technology, MVR technology and flash technology. Among them, MVR technology compresses the secondary steam through the compressor, increases the pressure and saturation temperature, directly uses it as heat to replace fresh steam, at the same time without cooling treatment, the operation cost is relatively low.

When the wastewater is less and the content of recyclable materials is higher, the operating cost and return of zero discharge technology have strong advantages compared with the standard discharge of traditional lithium battery wastewater. Generally speaking, if the concentration of wastewater is low, the membrane treatment can be conducted first, after concentrated go into the evaporation crystallization system for treatment.

If all the excessive domestic sewage and the cleaning wastewater with low concentration adopt the zero discharge process based on evaporation, the cost is too high. In practice, the lithium cleaning wastewater after coagulation and precipitation is often mixed with the domestic sewage of the plant area and then go into the biochemical treatment system, which improves the biochemistry of the wastewater, and the effluent can be discharged up to standard.

- High-temperature calcinationprocess

Fire metallurgy process is simple and easy for industrialization, but organics such as electrolyte, will produce harmful gases under high-temperature calcination, which needs to be treated, so the disadvantages of this method are high energy consumption and high cost.

- Hydro-metallurgy process

Hydro-metallurgy is a very mature process, which can be used alone or combined with other processes. It has the advantages of low cost and low requirements of equipment, but has the disadvantages such as incomplete recycling of waste batteries and long process of treatment.