I. Are you aware of the importance of high salinity solution treatment?

High salinity solution generally refers to effluent bearing significantly higher salinity than that of conventional surface water or ordinary production and domestic water. Its total salt mass fraction stands at least 1%, containing not only massive inorganic ions like Cl–, SO42-, Na+, and Ca2+, but also organics such as oil, heavy metals, radioactive substances, and non-degradable matters.

It will result in:

- Disruption of freshwater ecosystems,

- Inhibiting the development of organisms in the ocean,

- Crippling the economic development, due to its high treatment-cost

- Damaging the soil structure, leading to crop death and food production reduction,

- Bringing water pollution diseases, such as gastroenteritis and calculi, and harming human skin directly.

To apply our latest national regulations that the effective treatment measures to the high salinity solution shall be deployed for those regions without equipping the sewage classification system, to avoid the contamination of the groundwater, atmosphere, soil, etc, the implementation of the salt resource recovery of ZLD treatment demands urgent action.

II. How to deal with the high salinity solution and conducting the Na2SO4 extraction?

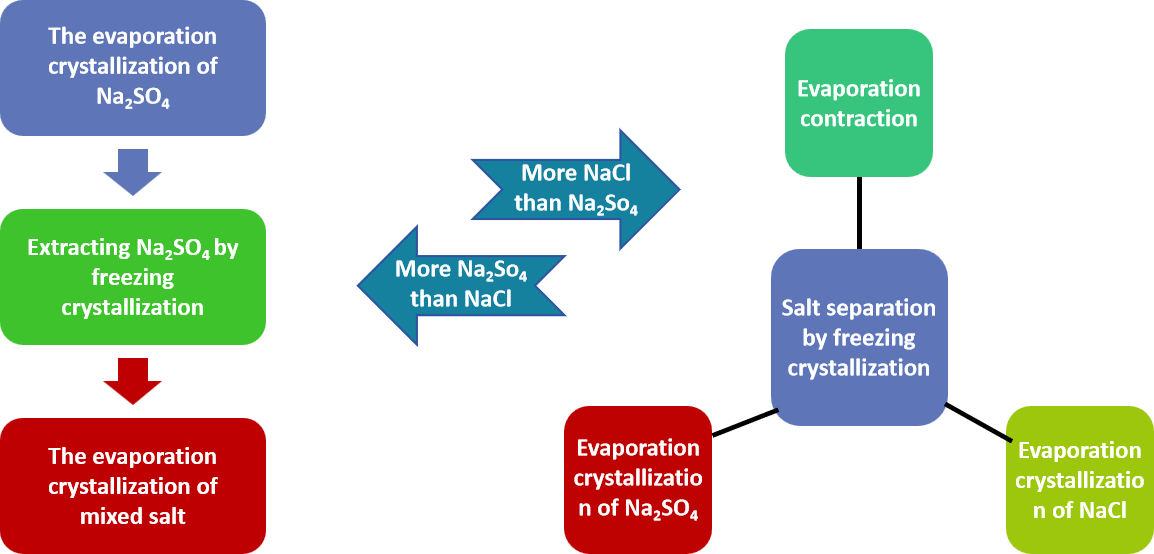

The salt separation by MVR Evaporation, MEE Evaporation and Freezing Crystallization processes serve as the major methods to realize the ZLD and crystal salt resource recovery. By adopting such treatments to the mine water or coking wastewater, treasures will be salvaged from that waste, which will reduce the operating and treatment costs.

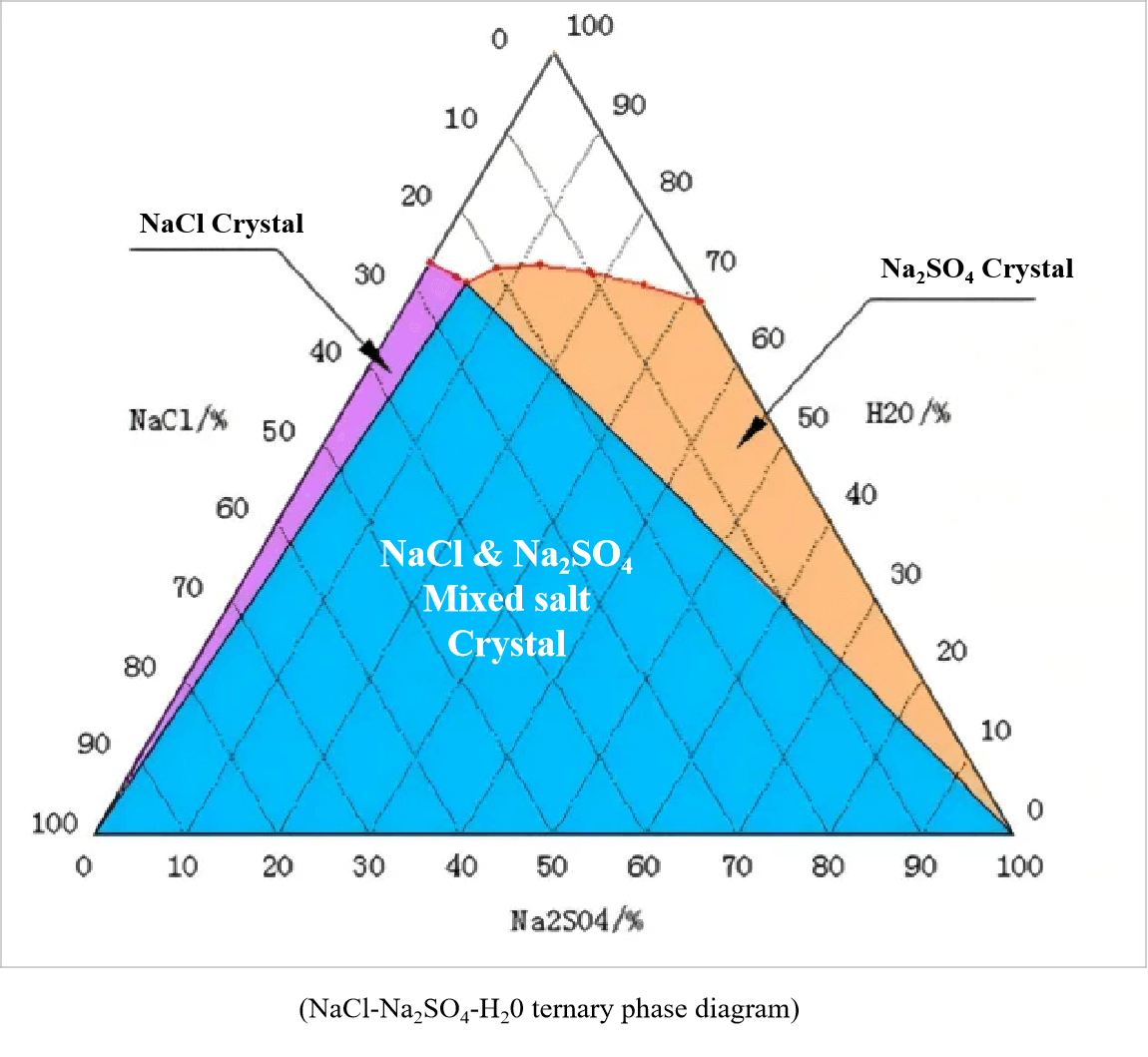

The solution of mine water and coal-chemical mainly contains Na2SO4 and NaCl. According to their different solubility varying from the temperature, the ternary phase diagram reads that they can be separated by different salt separation processes.

- How to obtain the pure Na2SO4 salt if there is a slight concentration difference between the NaCl and Na2SO4?

Solution: Combing thermal evaporation crystallization and freezing crystallization

Process:

-

-

-

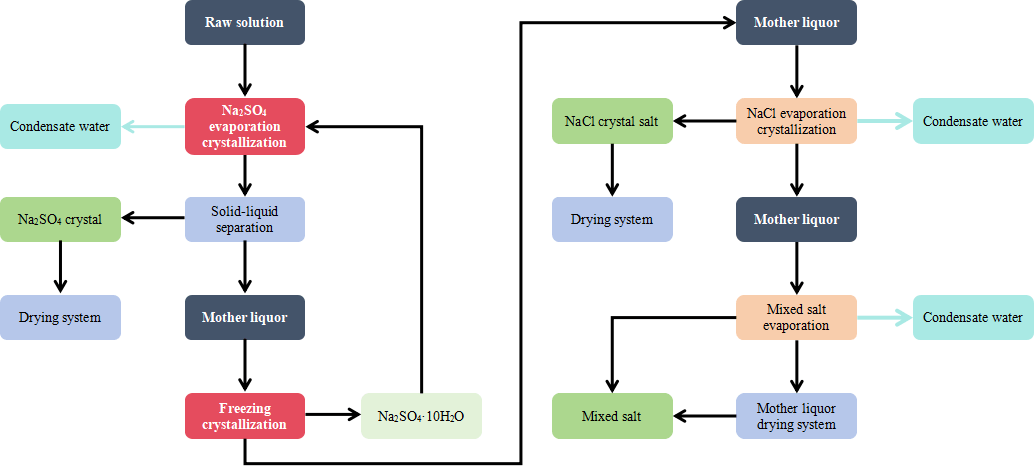

Extract the Na2SO4 by evaporation crystallization.

-

Through freezing crystallization, extra the Na2SO4·10H2O from the mother liquor treated by the centrifuge.

-

The Na2SO4·10H2O circles back to the evaporation and crystallization system for the Na2SO4 salt extraction.

-

The remaining mother liquor flows into the NaCl evaporation and crystallization system for NaCl salt extraction.

-

Extract the remaining mixed salt from the previous mother liquor by evaporation concentration & drying.

-

-

- How can we even get high-purity Na2SO4 salt if both NaCl and Na2SO4 feature a low concentration with a similar amount?

Solution: Combining concentration, freezing crystallization and recrystallization

Process:

-

-

-

Allow the Na2SO4·10H2O precipitate by conducting evaporation concentration and freezing crystallization in an order.

-

By adopting recrystallization, extract Na2SO4 salt.

-

Extract NaCl salt from the previous mother liquor by evaporation crystallization.

-

Extract the remaining mixed salt from the previous mother liquor by evaporation concentration & drying.

-

-

- How can Na2SO4 salt extraction be conducted if the high organic concentration solution contains more NaCl than Na2SO4?

Solution: Combining freezing crystallization and recrystallization

Process:

-

-

-

Freezing crystallization can be adopted directly to allow the Na2SO4·10H2O precipitate.

-

Extract high-purity Na2SO4 salt by recrystallization.

-

Extract NaCl salt from mother liquor.

-

Extract the remaining mixed salt from the mother liquor by evaporation.

-

-

III. Why choose Sanfeng tech.?

- Advantages

As a well-known professional evaporation system general contractor, with abundant experience and innovation, Sanfeng specializes in the treatment process of salt separation and high salinity and COD solution evaporation, such as the solution disposal of NaCl, Na2SO4, (NH4)2SO2, NH4Cl, KCl, etc.

Many years have witnessed the efforts of Sanfeng in the eco-friendly field of solution disposal. By involving massive resources and reserved technologies, Sanfeng has achieved many successful MVR evaporation system cases.