- Basic ZLD Process of Desulfurization Wastewater

- Pretreatment:

Chemical Precipitation

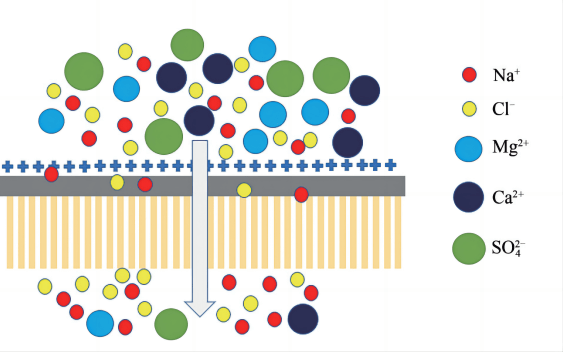

Tube Microfiltration (TMF)

Membrane

- Concentration:

Multi-effect evaporation concentration(MEE)

High-temperature bypass flue gas concentration

Ultrafiltration (UF), Nanofiltration (NF)

- Drying system:

Spray drying of the main flue and bypass flue

High-speed rotary spray drying

- The Typical Evaporation Process:

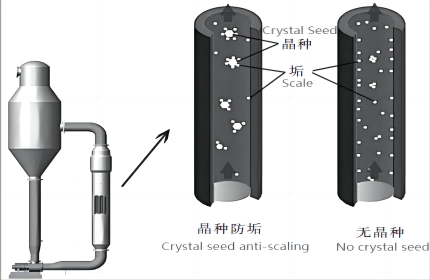

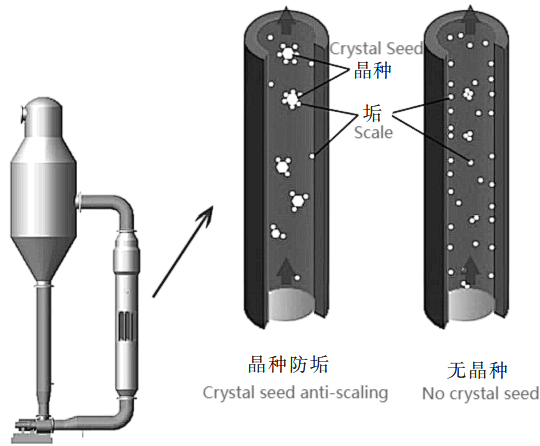

- Crystal Seeding Method

Working principle:

In the evaporation process, with appropriate amount of crystal seed to maximize the delay of system scaling. During the evaporation and concentration, the system can maintain enough crystal by adding or reflux. The specific surface area of the crystal is much greater than the wall of the heat exchange tube. Most of the newly generated crystals (scale) will gradually grow with the crystal as the core, so as to avoid scaling attached to the inner wall.

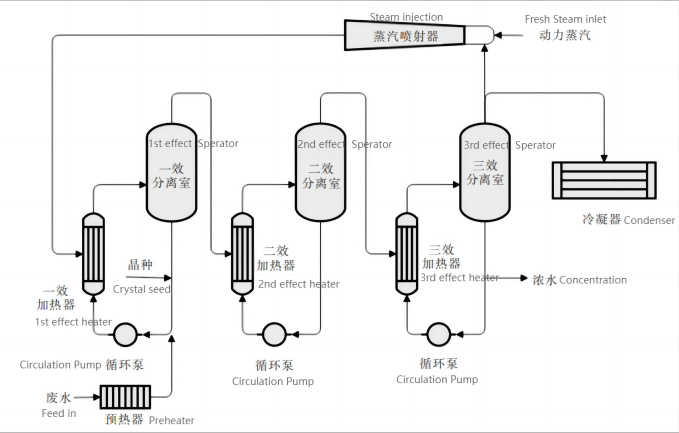

Technical Process:

The secondary steam generated by the previous evaporation is used as the heat source for the next effect evaporator, so as to fully utilize the latent heat of the secondary steam in the system and save energy consumption. The vacuum pump extract the noncondensable gas of the evaporation system to meet the vacuum requirements of the system. In the operation, the crystal reflux and monitoring are adopted to ensure enough crystal quantity in the system, so as to achieve the best scale prevention effect.

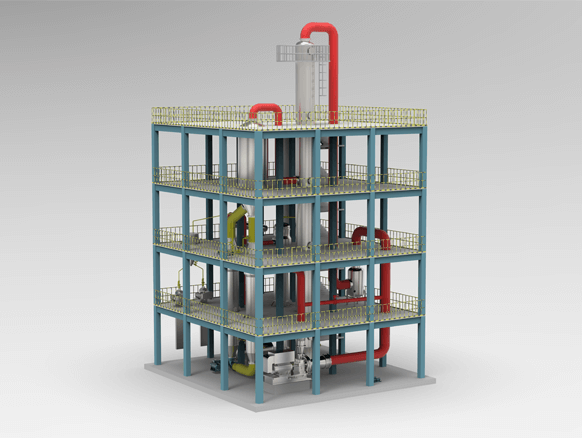

- Multi-effect Evaporation/MEE

Some of the cases, the CaSO4 is contained in the effluent. Then, the effluent should be treated with MEE directly to save the cost. The multi-effect evaporation (MEE) concentration process is: the first effect uses the fresh steam or waste heat as the heat source; the second effect uses the secondary steam as the heat source; and the third effect uses the secondary steam of 2nd effect as the heat source, so as to fully utilize the latent heat of the secondary steam in the system and save energy consumption.

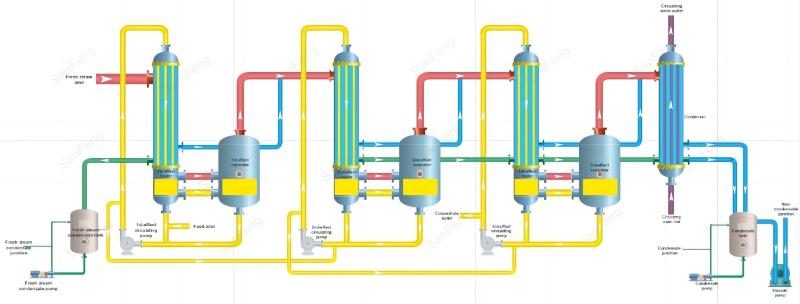

- Typical Case in Sanfeng Tech:

Take below case for example:

- Project: ZLD of desulfurization wastewater from a power plant

- Place: Hubei province, China

- Process adopted: MEE Three-effect low-temperature flash process

- Treatment goal: To concentrate and ZLD zero liquid discharge

In this case, the steam generated is extracted as the heat source of the evaporation system. Then the concentration is dried by the rotary spray drying device. Our company has successfully passed the continuous 168h performance test.

Up to now, it is still running stably, and the evaporation capacity has no attenuation tendency, all parameters have reached the design index.

For more detailed information about our wastewater treatment, you can click this link Home – Sanfeng (sanfengtech.com)to our website or leave a comment to us. Warmly welcome to send email to us for a solution! Let us inspire you.