I. How does mine wastewater disposal benefit our society?

With its realization of energy savings and boosting healthy economic growth, mine wastewater disposal also improves the local environment.

It benefits our society in these ways:

- Value industrial-grade salt recovery,

- Pollution elements removal in the discharged material,

- Discharged wastewater purification for civil usage.

For example, in China, the implementation of mine wastewater disposal not only recovers the industrial-grade salt, but also the valuable resource of clean water, which benefits the residents in the Center-North and Northwest of the mainland mostly haunted by the water shortage, such as the provinces of Inner Mongolia, Xingjiang, and everywhere in between.

II. What method can be carried out for the treatment of mine wastewater?

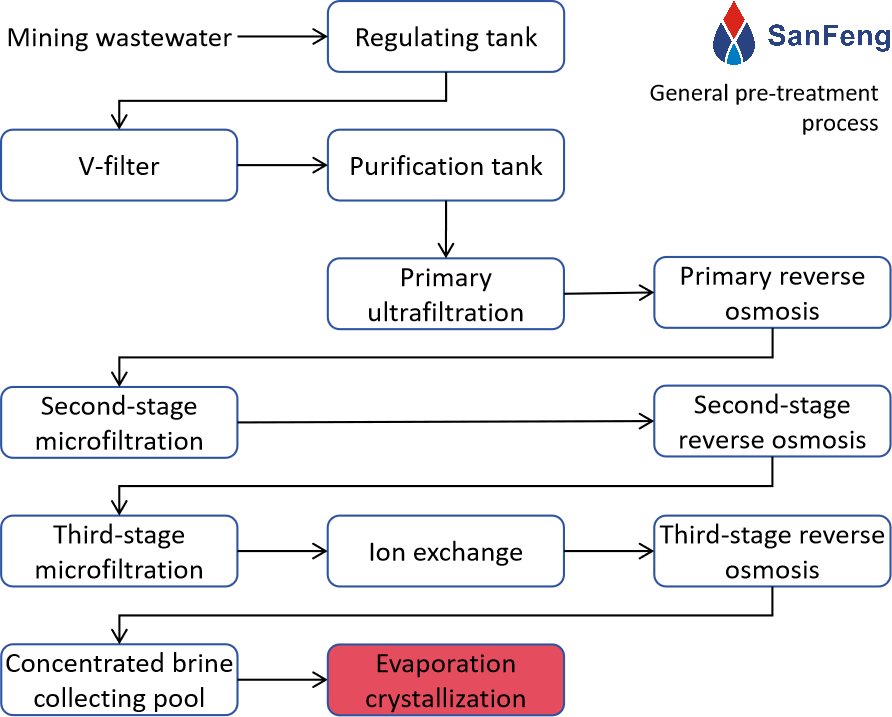

Currently, such treatment is majorly constituted by 2 parts. One serves as the pre-treatment, followed by the evaporation crystallization.

- Pre-treatment

The pre-treatment removes the SS and some of the TDS, reducing the volume of the wastewater, as well as promoting the TDS dissolution, resulting in the surge of the TDS mass concentration to meet the demand for evaporation.

It normally involves:

-

- Regulating tank.

- By dosing flocculants such as PAC & PAM, the impurities like organic matter, oil, and heavy metal ions, are precipitated and separated in the regulation tank.

- V-filter

- The V-shaped inlet ensures the wastewater even distribution. Then, assisted by the coarse and even placed filter materials, most of the suspended solids & impurities are filtered.

- Purification tank

- With a long standing time, the remaining oil floats, while the high-density impurities precipitate driven by gravity.

- Micro-filtration

- With a forced pressure ranging from 0.07 to 0.2MPa, the micro-filtration separates the particles sizing more than 0.02 to 10μm in the wastewater, serving as the prefilter to protect more precise filters in the coming process.

- Ultra-filtration

- During ultrafiltration, the micropore is able to remove microbiological contaminants, such as germs and viruses, without any chemical dosing.

- Reverse osmosis

- The semipermeable membrane serves as the core element in the reverse osmosis (RO) system, separating the macromolecule impurities from the micromolecules and ions. Such purification avoids the system blocking or even damage in the coming treatment.

- Regulating tank.

- Evaporation crystallization

As the key element of realization of ZLD disposal, evaporation crystallization, (such as MVR & MEE evaporation crystallization as well as freezing crystallization), serves as the last operation procedure.

In normal, the pretreated mine wastewater is loaded with Na+, SO42-, and Cl– majorly.

Sanfeng Tech can provide you with a comprehensive solution on this matter!

In Sanfeng Tech`s live cases, the process details will be designed according to the proportion between NaCl and Na2SO4, as well as the requirements on yield salt quality.

By the combination of the following self-developed & manufactured elements, an elaborate system will meet the purchaser`s demand in every aspect:

-

- Vapor compressor

- Falling film evaporator

- Crystallizer (OSLO, DTB crystallizer, etc)

- Thickener

- …

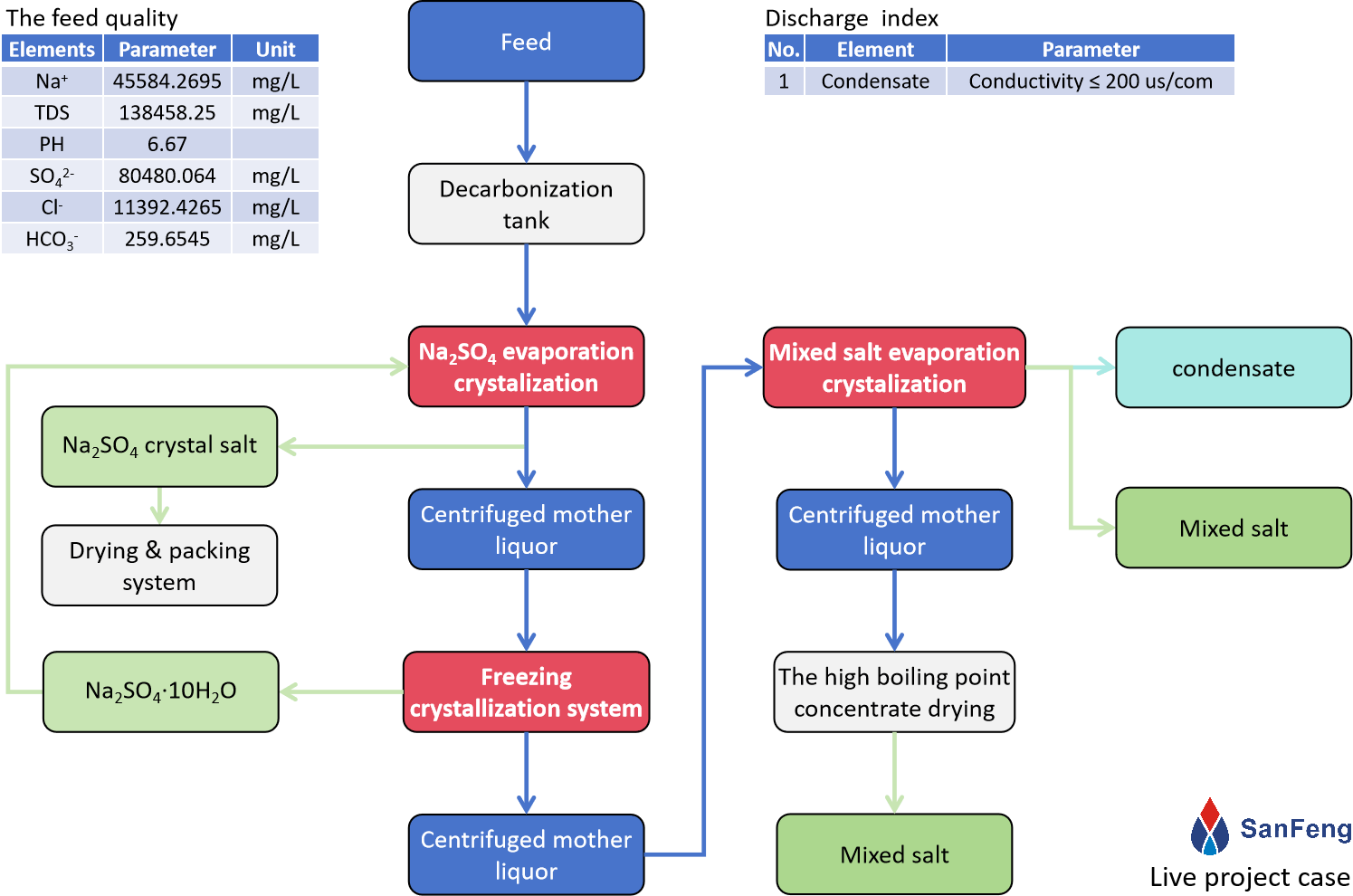

III. Live project case in Sanfeng Tech

In one of our project cases, the following demand has been raised:

- Feed quantity:

- High content of Na+(45584.2695 mg/L) & So42- (80480.064 mg/L)

- Low content of Cl– (11392.4265 mg/L)

- Low content of HCO3– (259.6545 mg/L)

- pH 6.67

- Feed volume: 14m³/h

- Discharged condensate: Conductivity ≤ 200 us/com

With the mine wastewater containing Na2SO4 majorly, the following processes have been adopted:

- Industrial-grade Na2SO4 salt extraction

- ExtractNa2SO4, by adopting the MEE evaporation system combining the following major elements:

- MVR evaporation crystallization

- Dryer

- Ton packing unit

- …

- To raise the Na2SO4 recycle rate, freezing crystallization is adopted for separating the remaining Na2SO4•10H2O from the centrifuged mother liquor of the previous process.

- Redissolving the Na2SO4•10H2O for thermal evaporation serves as a solution consuming less energy, and ensuring a high profit.

- ExtractNa2SO4, by adopting the MEE evaporation system combining the following major elements:

- The realization of ZLD

- As the investment for further salt extraction exceeds its rewards, the mixed salt thermal evaporation can be carried out directly, resulting in its discharge containing less than 10% moisture.

- To ensure the evaporation operation efficiency, the discharge of the high boiling point concentrate needs to be carried out, after drying.

- The condensate collected from the evaporators features a conductivity of less than 200 us/com.

With our experts’ elaboration study, such a system has fulfilled its purpose with the following discharges:

- Industrial-grade Na2SO4 salt with high purity & large particles

- Condensate with a conductivity of less than 200 us/com