Technical Introduction

The Mechanical Vapor Recompression(MVR) technical provides the evaporation system with a new energy supply solution by supercharging the secondary steam. As an alternative solution, the MVR surpasses the utility fresh steam supply in:

- Compact structure

- Energy efficiency

- Stable operation

- High automation

The distillation realizes the solution’s purification and concentration. As a common and mature process, it relies on the volatility difference from the compound in the solution. In the distillation column, the light component of the heated solution rises, meanwhile, the heavy counterpart falls.

It is normally adopted for:

- Chemical extraction

- Food processing

- Environmental engineering

The introduction of MVR for the distillation system

The introduction of MVR into the distillation system has greatly taken advantage of the secondary steam. It reduces the operation cost by cutting off the massive consumption of:

- Fresh steam

- Circulating water

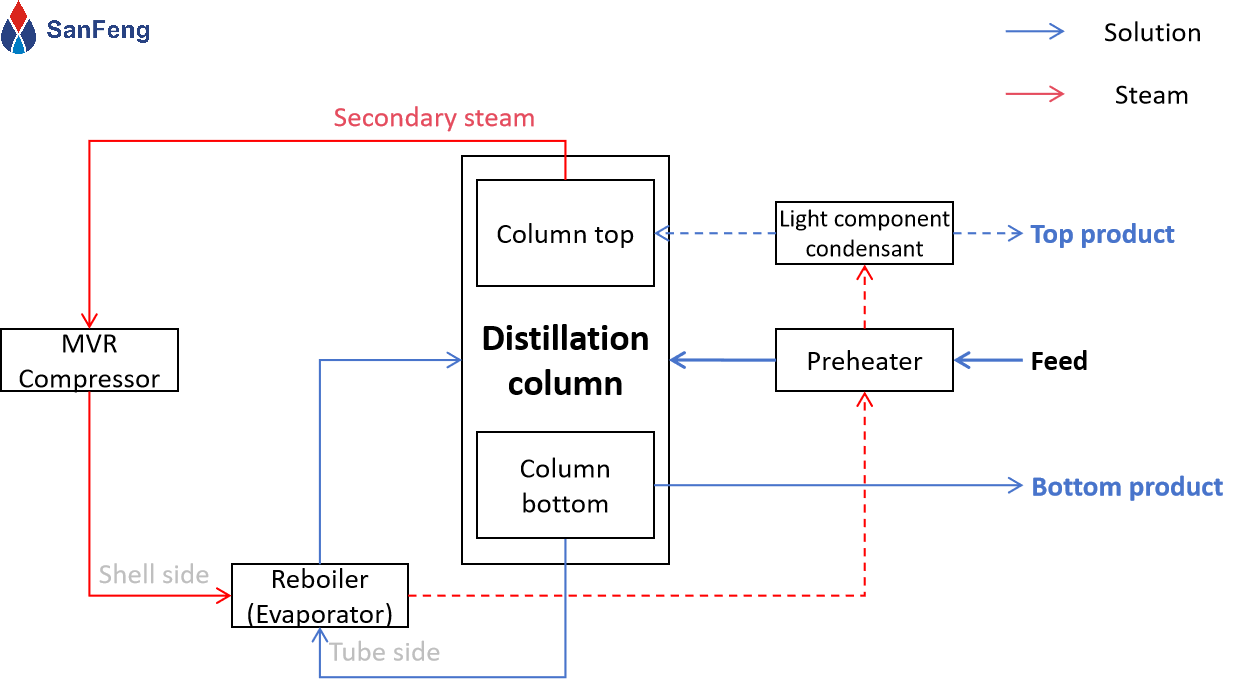

From the top, the light component steam is directed to the MVR compressor for recompression, to increase its pressure and temperature.

Then it is injected into the shell side of the evaporator for heat exchange, and collected as condensate after being cooled.

Only the condensate with high COD is discharged, and the rest condensate is either returned to the distillation system or collected as the product.

Project Case

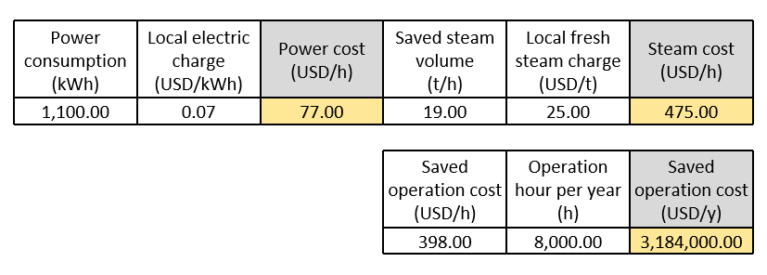

Such as Sanfeng‘s successful monomethylhydrazine production case, it features:

- Feed solution: 2.3% monomethylhydrazine concentration

- Process capacity: 13t/h

- Product: 47% monomethylhydrazine concentration

With its smooth operation, it has saved approximately 3.18 million USD per year in operation costs only for our client.

Prospect of the distillation application

As most of the organic matters feature low boiling point elevation, this technology has a vast application prospect in the field of organic matter distillation.

Processing distillation project experience, Sanfeng has designed different type of MVR compressors applying to the distillation of different materials. Based on that, Sanfeng Tech now has multiple successful MVR distillation cases involving in the production of:

- Methyl alcohol

- Ethyl alcohol

- Acetone

- Propargyl alcohol

- Dimethyl Formamide(DMF)

We are confident in providing our client with a cost-efficient solution, facing any challenges, and exploring all the possibilities in the field of distillation!