Forced Circulation Evaporator

What is forced circulation evaporator?

The forced circulation evaporation system uses the external power of the forced circulation pump to keep the material in a stable circulation flow in the equipment, so that the material is heated evenly and achieve a better evaporation effect. This system is suitable for the concentration of materials with high viscosity, easy fouling or easy crystallization.

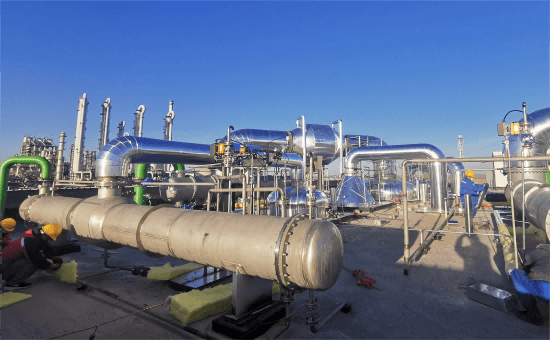

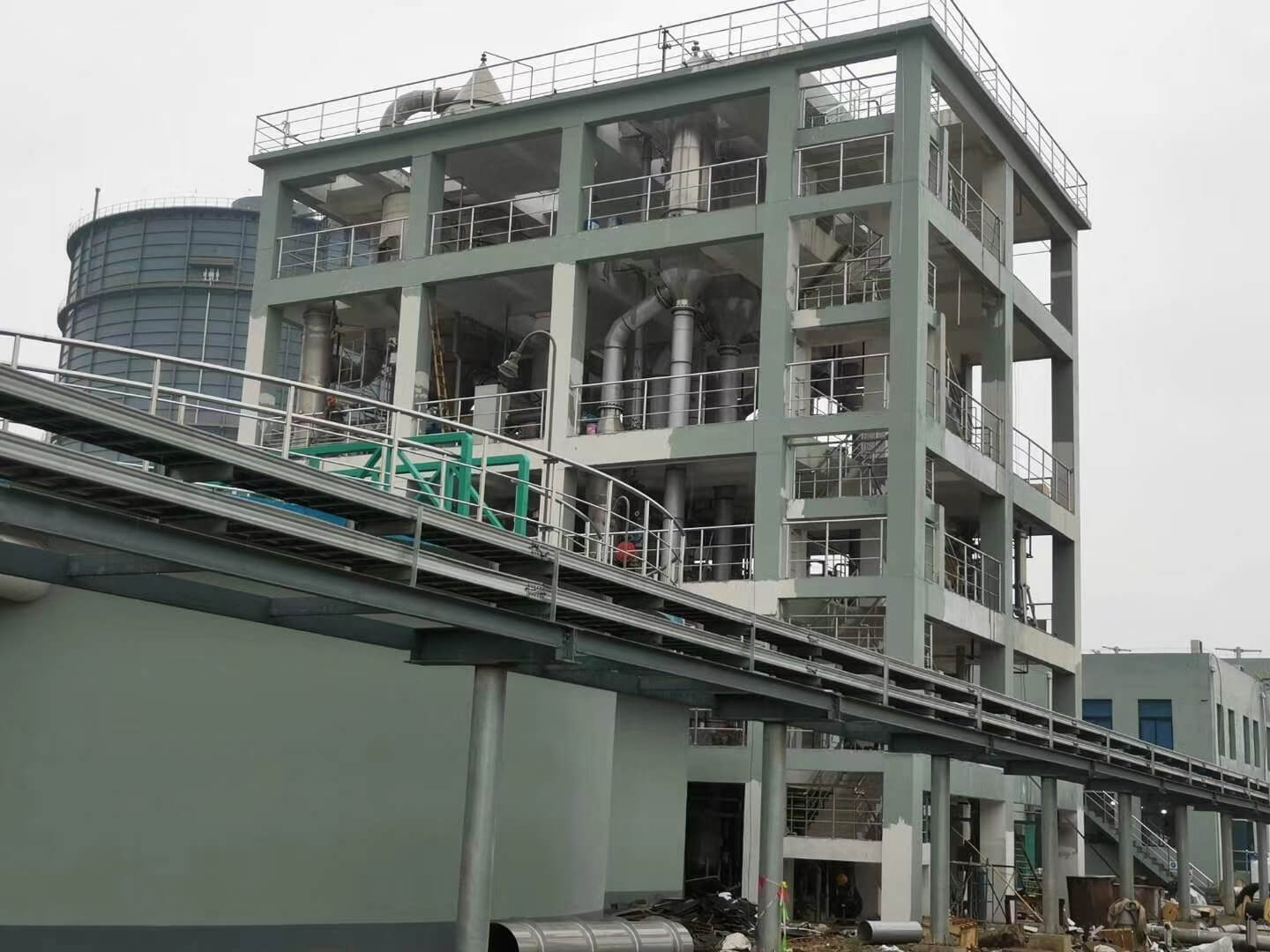

The Forced Circulation Evaporator in Sanfeng Tech

- In the multi-effect evaporation system, the forced circulation evaporator used as a high concentration step to process materials that are easy to scale and viscous materials.

- In the MVR evaporation system, forced circulation evaporator is mainly used, to treat high TDS brine effluent and high viscosity feed.

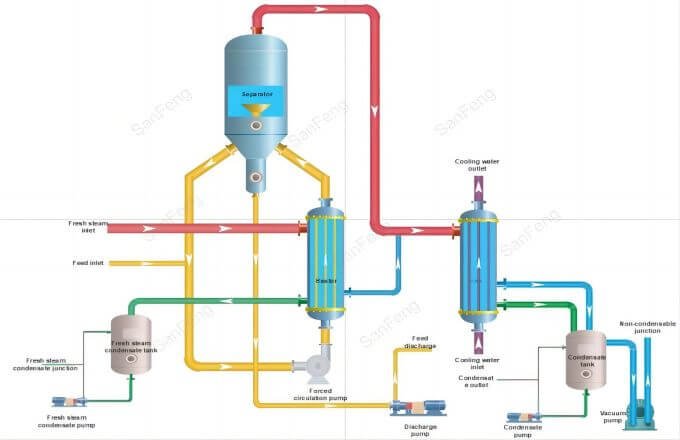

Composition of the Evaporation System

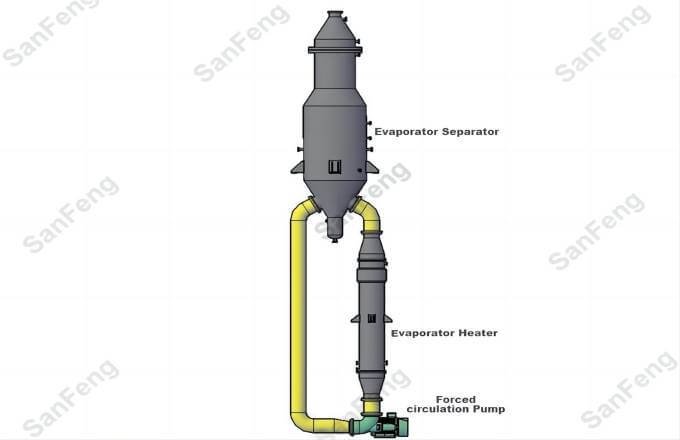

- Evaporator Heater

- Evaporator separator, Condenser

- Forced circulation pump

- Delivery pump

- Vacuum pump

- Control system etc.

What is the working method for forced circulation evaporator?

The forced circulation evaporator is mainly composed of a heater and a separator. A circulating pump causes the liquid to circulate in the tube at a flow rate of 1m/s to 5 m/s, and it is heated to overheating at a higher than the normal boiling point of the liquid by 1~ 3°C, after entering the separator, the pressure of the liquid drops rapidly, causing part of the liquid to flash and the material is concentrated. For multi-effect evaporation, the secondary steam produced by evaporation enters the next-effect evaporator for heating or enters the condenser; for MVR evaporation, the secondary steam enters the vapor compressor.

Features and Advantages

- The flow rate is high, and the flow rate in the tube is determined by the circulating pump.

- Long running time, evaporation does not occur on the heating surface, flash evaporation occurs in the separator.

- It can minimize the scaling and blocking caused by the fouling and precipitation in the pipe.

- The material quickly circulates through the heating tube, and the liquid separation process occurs in the separation chamber, so the possibility of scaling is greatly reduced.

- It widely used for high concentration ratio processing which need to keep good fluidity.

- High circulation speed will increase the fluidity of the material which can also improve the heat exchange efficiency.

- Highly stability with easy maintenance and operation work;

- Fully automatic control system which have control point of feeding, evaporating, discharging.

Main Applications

- Forced circulation evaporator is most suitable as a crystallization evaporator for brine solution, especially when TDS is high.

- In the multi-effect evaporation system, it is used as a high concentration step to process materials that are easy to scale and viscous materials.

- In the MVR evaporation system, a forced circulation evaporator is mainly used.