Falling Film Evaporator

What is falling film evaporator?

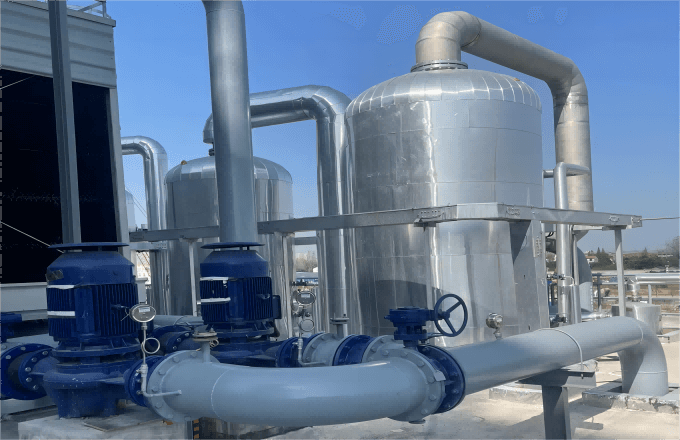

The falling film evaporator is divided into tubular falling film evaporator and plate falling film evaporator according to the structure form. It is also divided into vertical pipe falling film evaporator and horizontal pipe falling film evaporator according to the form of cloth film.

The above forms all separate the heated material liquid from the heating medium through the heat exchange tube (plate), and the material liquid evaporates on the heated side to produce a mixture of steam and liquid phase to enter the separation chamber.

Working principle of falling film evaporator

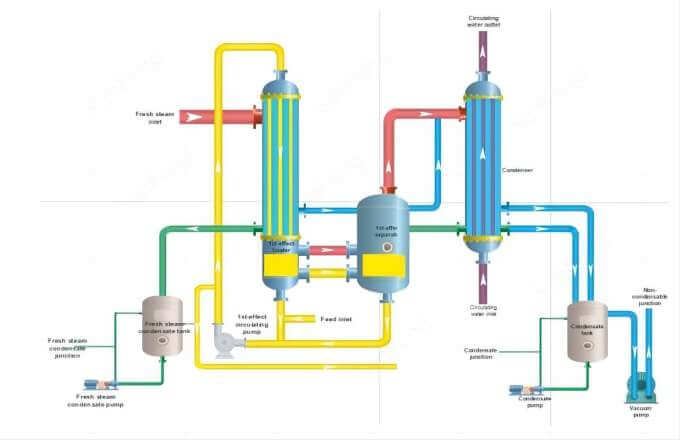

It is by adding the material liquid from the upper tube box of the upper tube of the heating chamber of the falling film evaporator, the material liquid is evenly distributed into the heat exchange tubes through the distribution and film forming device, and forms a uniform film under the action of gravity, vacuum induction and air flow the shape flows from top to bottom.

The material liquid is heated and vaporized by the shell-side heating medium during the flow process, and the generated steam and liquid phase enter the separation chamber of the evaporator together.

After the vapor and liquid are fully separated, the steam enters the condenser for condensation (single-effect operation) or enters the next stage of evaporation the device is used as a heating medium to achieve multi-effect operation, and the liquid phase is discharged from the separation chamber.

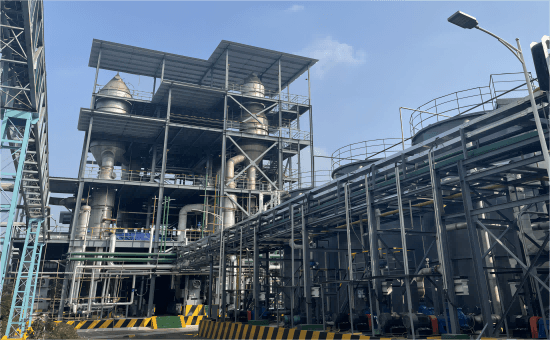

The Falling Flim Evaporator in Sanfeng Tech

- In the temperature-sensitive feed evaporation, the falling flim evaporator used in the Multi-Effect Evaproation system to concentrate the feed in the food industry, the pharmectical industry etc.

- In the low TDS evaproation, the falling flim evaporator used in the Multi-Effect Evaproation system, to concentrate the CSL, Glucose ect in the food industry, to treat wastewater from the textile industry, the pharmectical industry etc.

Advantages and characteristics

- Falling film evaporator can evaporate materials with higher concentration and higher viscosity.

- The heat transfer coefficient is high, as a film is the single-pass evaporator.

- Suitable for processing heat-sensitive materials.

- Falling film evaporator can operate quickly according to changes in energy supply, vacuum degree, feed volume, concentration, etc.

- Low temperature difference evaporation can be used.

- Falling film evaporator is suitable for foaming materials.