Pretreatment

What is the common pretreatment method before the evaporation system?

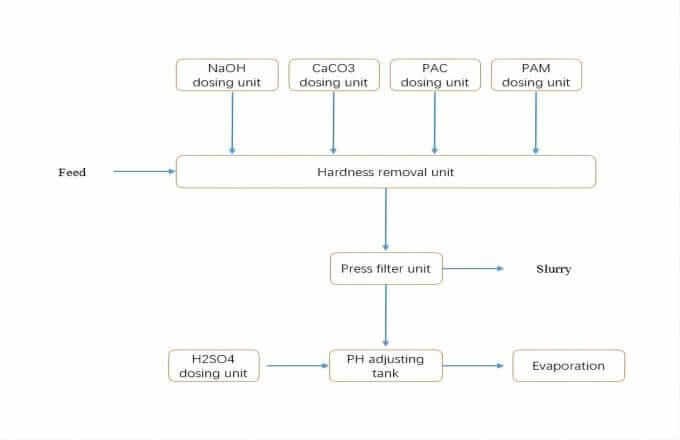

In order to avoid blocking and scaling in the evaporation system, some pretreatment should be done prior to the evaporation system.

- Degasification

- Oxidation

- Softening

- Flocculation

Degasification

Degassing is mainly to remove the small amount of non-condensable gases dissolved in the high salt wastewater and leaked from the device, mainly including oxygen, nitrogen, carbon dioxide, etc. The purpose is to increase the heat exchange efficiency and reduce the corrosion of wastewater on metal materials (oxygen plays a role in promoting corrosion).

Oxidation

The decomposition of oxidant is enhanced by using catalyst to accelerate the chemical reaction between pollutants in wastewater and oxidant to remove pollutants in feed.

Advanced oxidation technology has good effect on treating high concentration of toxic and harmful wastewater that is difficult to degrade.

Softening

Highly saline wastewater contains various salts which dissolve as cations and anions, mainly Ca2+, Mg2+, Na+ and HC03-, SO42-, Cl-, etc.

In order to eliminate or reduce these hazards, the feed should be able to form scale hardness components, such as calcium, magnesium ions, and other high-value metal ions such as iron, aluminum, manganese, etc., to be removed.

Flocculation

Flocculation and sedimentation method refers to adding a certain amount of flocculant to the wastewater to make physical and chemical reaction to achieve the purpose of water purification. When using polymer flocculants to treat various industrial water, industrial wastewater, domestic water, and domestic wastewater, it has the advantages of promoting water clarification, reducing the amount of sludge, facilitating the treatment of filter cake and burning less ash.

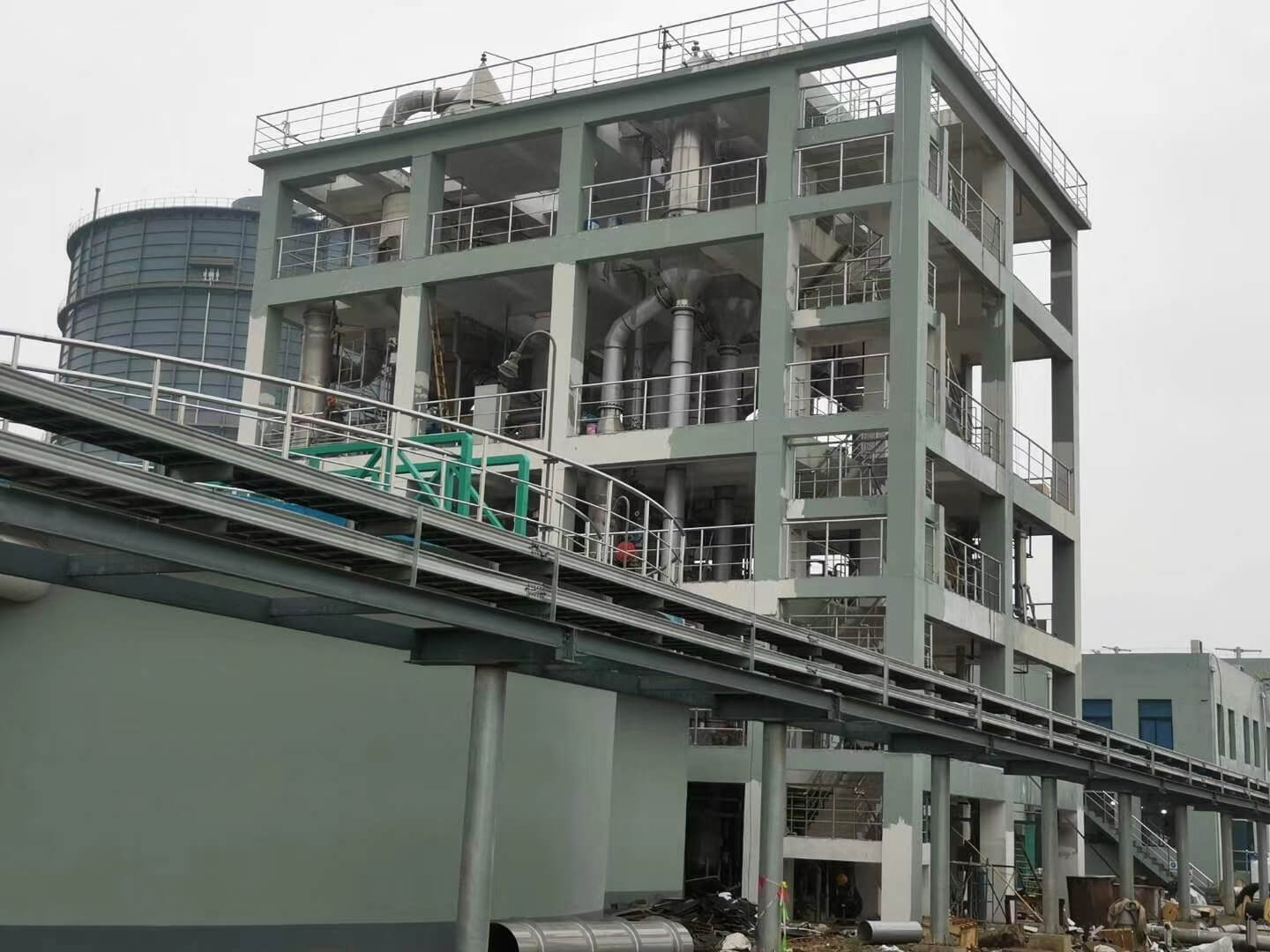

The typical process of the pretreatment before the evaporator in Sanfeng

Drying system

Three main types for drying system:

- Solid with 5% moisture, after treatment.

- Solid with 6~10% moisture, after treatment.

- Solid moisture less than 5%.