MVR Evaporation System

What is MVR evaporation system?

MVR technology is currently recognized as one of the most efficient energy-saving technology. It uses electrical energy to recover the energy of the secondary steam generated by itself, thereby reducing the need for external energy.

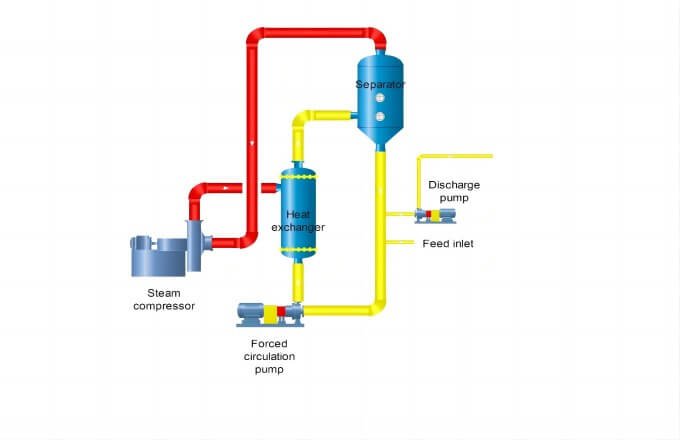

MVR evaporation system consists of :

- MVR steam compressor(also named steam centrifugal compressor)

- Heat exchanger(evaporator)

- Separator(crystallizer)

- Evaporative circulation pump

- Preheater

- Auxiliary tanks and pumps

- Control system, etc.

Working principle for MVR evaporation system

MVR evaporator converts electrical energy into mechanical energy so that the low-quality secondary steam in the MVR evaporation system is compressed by the compressor, and the temperature and pressure of the steam are increased, thereby increasing the enthalpy of the secondary steam, and then entering the heat exchanger to condense, making full use of steam latent heat. Compared with the traditional multi-effect evaporation system, the operation energy consumption of the MVR evaporation system is only 1/3~1/4 of the MEE evaporation system.

Features of MVR system when used in ZLD process

- High efficiency and energy saving. MVR evaporation system only consumes fresh steam during normal start-up. Most of the running time does not consume fresh steam or only a small amount of fresh steam, to supplement the normal heat loss of the evaporation system, which greatly reduces energy consumption and production costs.

- Compared with traditional evaporation system, MVR evaporator can provide smaller and more stable temperature difference heat transfer, which can achieve more gentler evaporation process. MVR evaporator is suitable for heat-sensitive materials, can improve product concentration quality, and can effectively reduce the risk of scaling caused by high heat transfer temperature differences.

- Small area, low civil engineering cost, and low consumption of supporting projects.

- Short process flow, simple operation, stable operation, can be equipped with CIP automatic cleaning device.

- The fully automatic control system can realize the smooth operation of the system and reduce the failure rate caused by human improper operation.

What Sanfeng offers based on MVR evporation?

Design the MVR evaporation system combines forced circulation evaporation and crystallization, falling film evaporation and crystallization and freezing crystallization to optimize the system with lower energy consumption and lower investment cost.

- Forced circulation evaporation and crystallation

- Falling film evaporation and crystallation

- Freezing crystallation

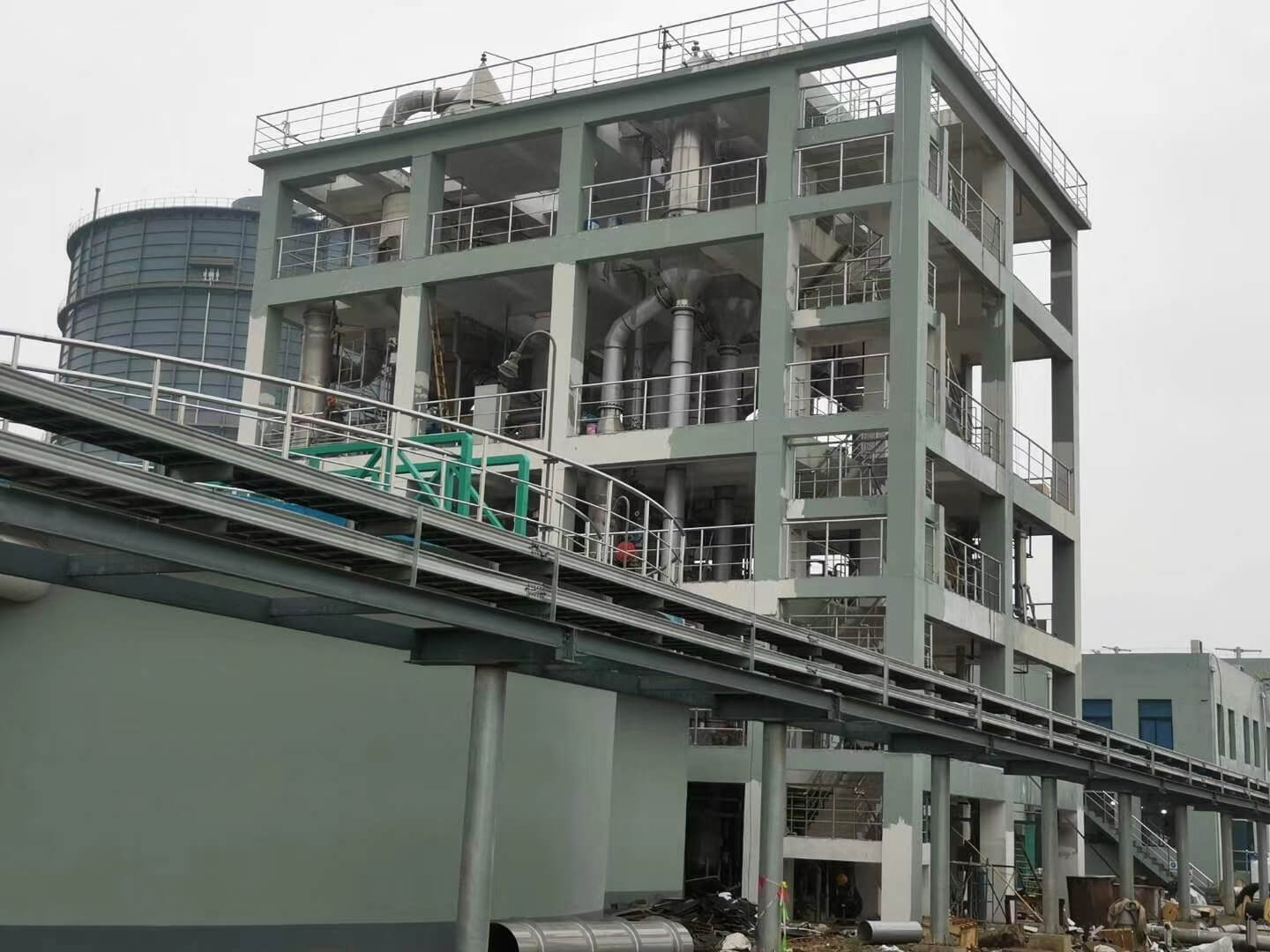

Special Engineering Design in Sanfeng Tech

- Steam compressor manufacturer

Sanfeng Tech brings the state-of-art technology, depth experience, and applications knowledge to industries, with 65 years of designing, production, and upgrading advanced manufacturer facility, including the mechanical vapor compressor solutions for any MVR Evaporator or Crystallizer application for Water Reuse, Concentration, Separation, Zero Liquid Discharge (ZLD), etc.

- Clearly 3D drawings

For corrective and effective design

For the installation and commissioning supervision

- Redesigned and Customized Automative Control System