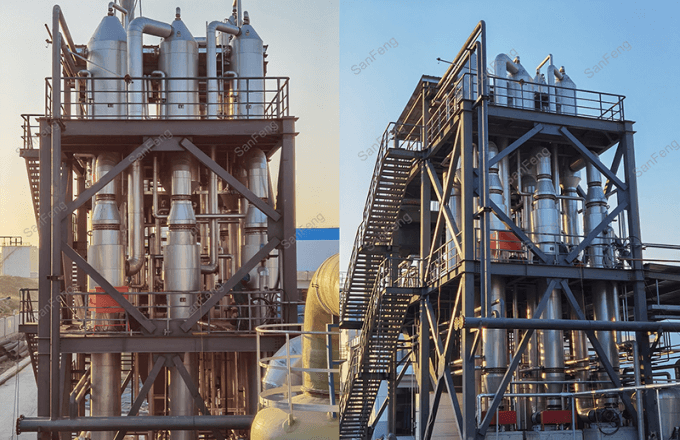

MEE Evaporation System

What is MEE(Multi-effect Evaporation) System?

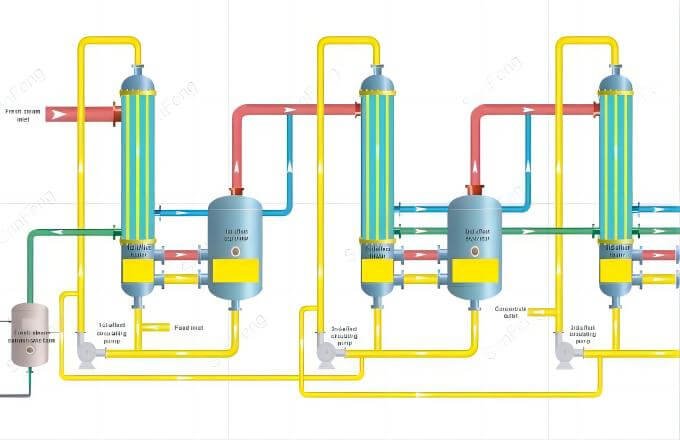

Multi-effect evaporator system is a system in which multiple single-effect evaporators are connected in series to achieve continuous evaporation. Since evaporation is a process that consumes a large amount of steam to generate secondary steam, in order to make full use of the waste heat of steam, generally the previous secondary steam is introduced into the next effect as a heat source. This maximizes energy utilization efficiency while ensuring evaporation.

The selection of the number of stages of the multi-effect evaporator depends on various factors such as the specific material properties, the concentration of the incoming and outgoing materials, the temperature, and the energy consumption cost. Generally speaking, more stages will result in lower steam consumption. Sanfeng is also committed to providing multi-effect evaporators and solutions suitable for various materials.

Main part of MEE Multi Effect Evaporation System

- Heat Exchanger (Evaporator)

- Separator(Crystallizer)

- Circulation Pump

- Vacuum Unit

- Automative Control System

How to choose evaporator type in MEE System?

Falling Film Evaporator and Forced Circulation Evaporator can be used in the MEE Multi Effect Evaporation System.

According to feed parameter and treatment destination, Forced Circulation. Evaporator is the mostly used type to treat the high TDS and high COD effluent.

Features & Advantages of MEE system

- According to the characteristics of the material and the size of the evaporation capacity, it can be designed as a single-effect or multi-effect evaporation unit, with flexible equipment combination and large operating space.

- The heat transfer coefficient of the multi-effect evaporation system is relatively high, the heating time of the material is short, and the evaporation temperature is low, which can effectively reduce equipment corrosion.

- The multi-effect steaming system makes full use of the latent heat of the secondary steam of the material to minimize heat emission and reduce the consumption of raw steam.

- The heat exchange tube of the multi-effect evaporation system is not easy to foul, with high heat transfer efficiency, large operating flexibility, reliable operation and long operating cycle.

Special Engineering Design in Sanfeng Tech

- Steam compressor manufacturer

Sanfeng Tech brings the state-of-art technology, depth experience, and applications knowledge to industries, with 65 years of designing, production, and upgrading advanced manufacturer facility, including the mechanical vapor compressor solutions for any MVR Evaporator or Crystallizer application for Water Reuse, Concentration, Separation, Zero Liquid Discharge (ZLD), etc.

- Clearly 3D drawings

For corrective and effective design

For the installation and commissioning supervision

- Redesigned and Customized Automative Control System