Heat pump distillation has the successful applications in chemical, food, pharmaceutical and agriculture industry; its media is methanol, DMF, dichloromethane.

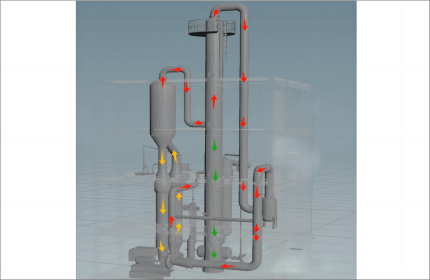

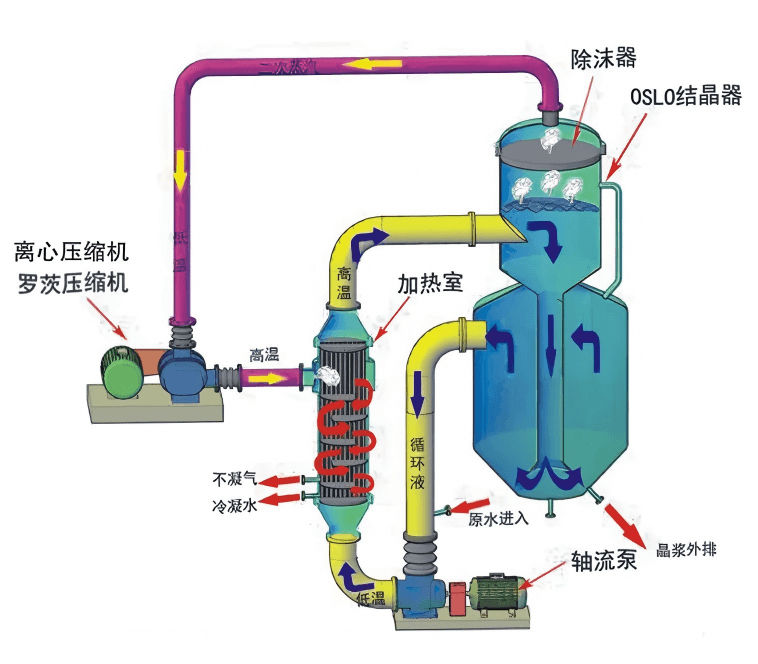

- MVR heatpump distillation technology

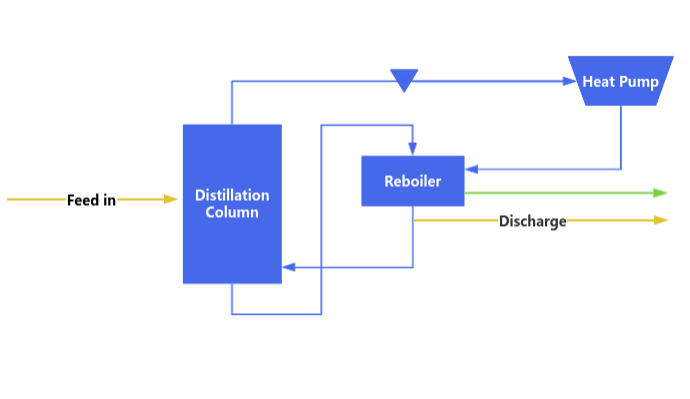

Working Principle:

The gas phase steam at the top of the distillation column is compressed by the heat pump to obtain the high temperature and pressure, which is used to heat the kettle liquid. After-heat of the steam is then recovered and utilized, so that the distillation system is completely self-circulating.

- Advantages & Cases of Heated Pump Distillation

Advantages:

- High efficiency &energy saving

- Heat transferred from low temperature medium to high throughthermodynamic inverse process

- Improve the efficiency of the separation process

- Solve the problems of traditional heating method: energywaste and equipment loss

- It usesheat pump to drive the compressor to heat the steam and then compress and release energy.

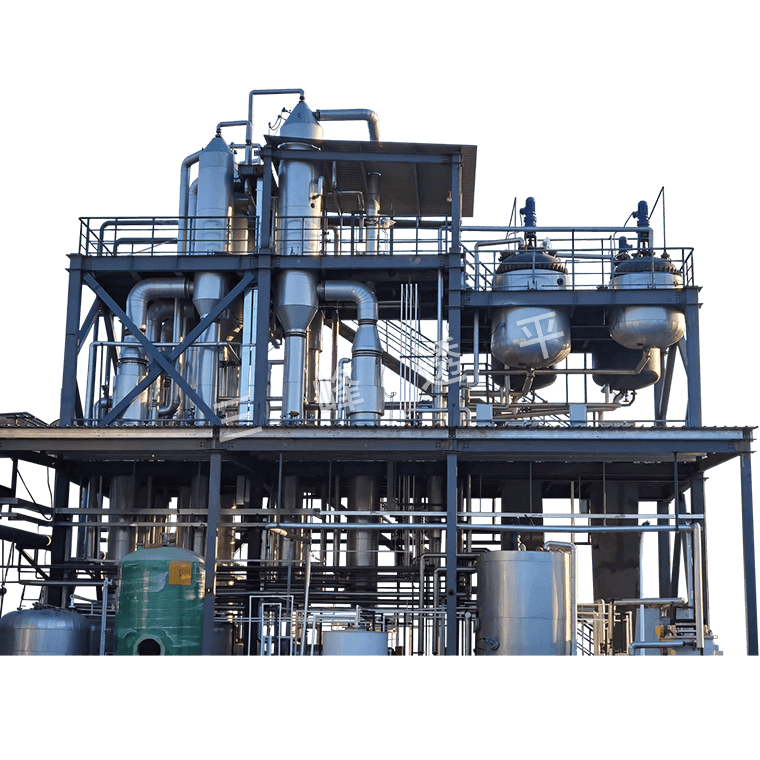

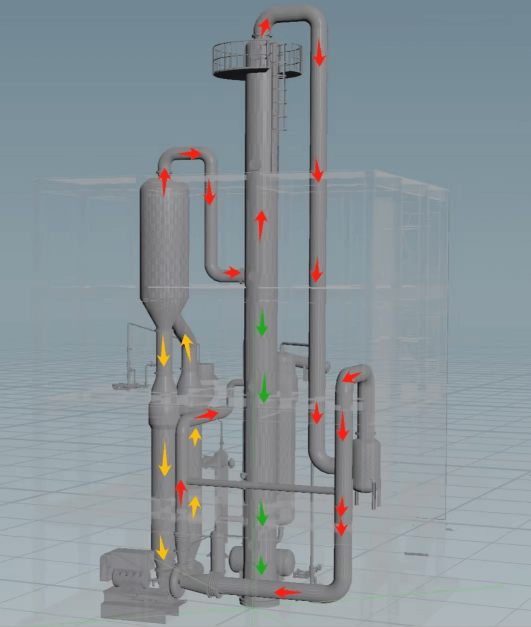

Typical Case in Sanfeng Tech:

Feed in: 5.5 t/h

Reflux: 1.5 t/h

Column Top Out: 3.5 t/h

Column Bottom Out: 1.75 t/h

Motor power: 560 kw

Before VS After:

Economic benefits: 10,690,000 CNY – 2,506,000 CNY = 8,184,000CNY

That’s what we saved by adopting our MVR heat pump distillation!

Before | Consumption | Source | Usage | Price |

steam | 5 t/h | CNY 270/t | ||

Cost/year | 5*24*270*330=10,690,000 CNY | |||

After | Consumption | Source | Usage | Price |

electricity | 452 kw/h | CNY 0.7/kw | ||

Cost/year | 452*24*0.7*330= 2,506,000 CNY | |||

- Summary:

In the distillation process, the heat pump technology can transfer the heat from the evaporator to the condenser, thus realizing the effective use of heat energy. It reduces the maintenance cost, improving the service life of equipment. The system is automatically controlled, so that it can realize the reasonable allocation of energy according to the process requirements.

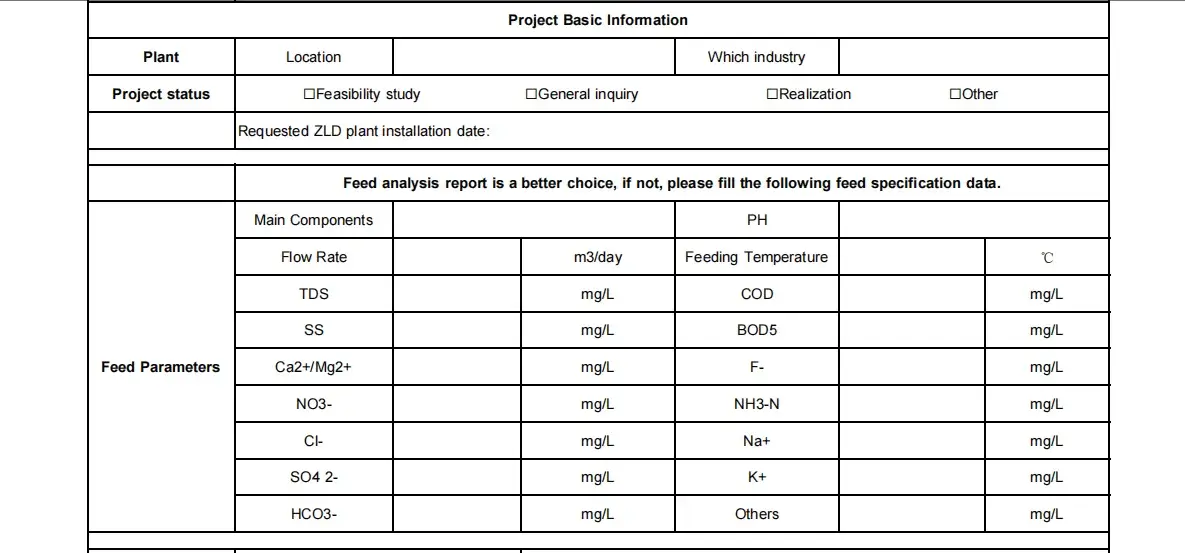

Are you trying to find out a perfect solution for your treatment? Let’s get started on your project now! If possible, contact us freely with your flow rate, chemical parameters or analysis, our expert will help and reply to you within 24 hours.