How Does MVR Work in Effluent Treatment?

- Introduction of the MVR evaporation process

MVR, is called a Mechanical Vapor Recompressor. The secondary steam from the evaporator, is compressed by the compressor, the pressure, temperature, and heat enthalpy of which increase, and then into the heat exchanger for condensation, to make full use of the latent heat of the steam, to reduce the external energy demand. It is an energy-saving technology. The core of MVR technology is to compress the secondary steam as a heat source instead of fresh steam.

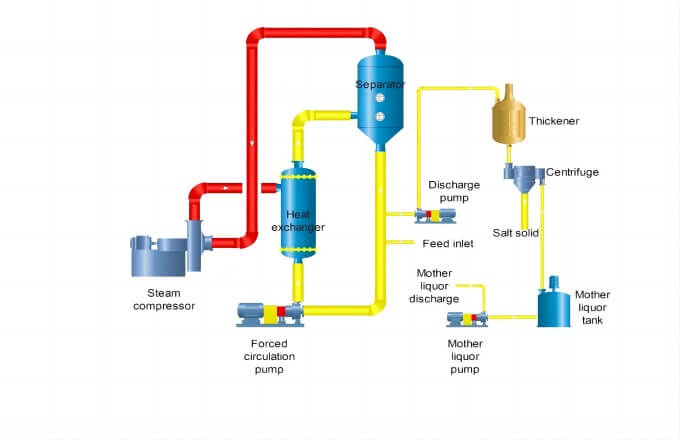

- How MVR works in effluent treatment

In the MVR system, the heat source in the preheating stage is mainly the fresh steam, until the material evaporates to produce steam. The secondary steam generated by heating the material is compressed into high-temperature and high-pressure steam through the compressor and serves as the heat source for heating. The material is constantly evaporated, and the steam through the compressor turns into condensate water by heat exchange, that is, the treated water. The whole system works through the compressor to realize the conversion of electric energy to heat energy and avoids the dependence and intake of fresh steam.

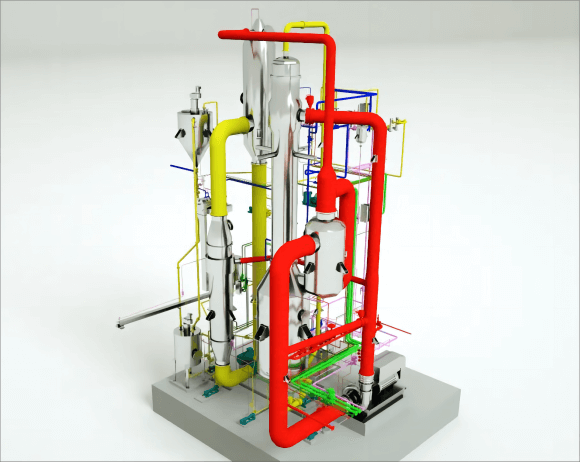

- The main components of the MVR system

Steam compressor:

The MVR compressor is the core equipment of MVR system, and its technical performance and production quality are crucial to the operation of the whole system.

Sanfeng adopts the advanced ternary flow impeller design, with the imported five-axis processing center, to ensure the excellent performance and timely delivery of the compressor.

- Features and advantages of Sanfeng’scompressor:

- No growth, high efficiency of the whole machine;

- High stability, low energy consumption, long service life;

- Small area, convenient installation and maintenance;

- High standardization, fast delivery.

Evaporator:

The evaporator is mainly divided into a forced circulation evaporator and a falling film evaporator.

Separator:

It plays the role of gas and liquid separation, material settlement, and crystal growth in evaporation.

Forced circulation pump:

Most are axial flow circulating pumps, suitable for large flow and low head.

Preheater:

Waste heat utilization and increasing the feed temperature

Control system, etc.:

The automatic control system, MVR evaporation system control center (DCS or PLC control center), and Automatic alarm.

Auxiliary tanks and pumps

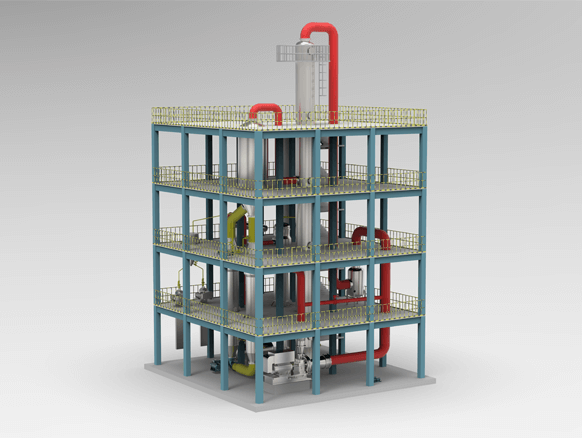

- MVR evaporation system in Sanfeng Tech

Sanfeng Tech is a company specializing in MVR evaporation systems, multi-effect evaporation systems, evaporation concentrations, freezing separation and other forms of evaporation and zero liquid discharge(ZLD). Relying on the technology advantage of core equipment, large-scale manufacturing platform, professional team with rich experience, according to different requirements, Sanfeng can provide the whole process and standardized system solutions, and can truly offer customized services for customers.

For more information about our MVR technology, you can refer to our website- MVR Evaporation System – Sanfeng Tech – Evaporation Solution Turnkey Supplier and contact us freely!