Freezing Separation System

What is Freezing Crystallization/Separation System?

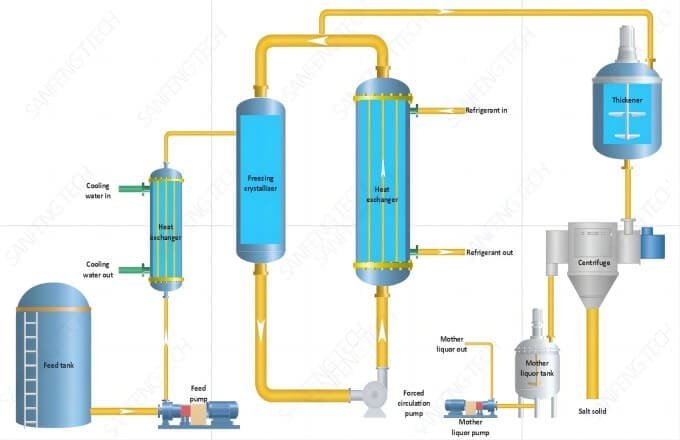

Freezing Crystallization System is suitable for processing such material which solubility significantly decrease during temperature decrease. Crystallization process will happen once the solution reach saturation. It is also suitable for treating some type of material which require stable crystallization environment to avoid burst formation of crystal core during crystallization process. Condenser is used in this system to keep the optimal material temperature which achieve stable crystallization temperature area.

How Freezing Crystallization System works?

Different from evaporation crystallization, freezing crystallization come from decrease of solubility. Solution will be getting saturated once the temperature decrease. But evaporation crystallization comes from evaporation of water in feeding material.

It is been proved that freezing crystallization suitable for such material which solubility curve shows a clear upward trend. Its solubility varies greatly with temperature.

The material continuously feeding and discharging in the system. The low temperature crystal slurry goes to filter section to get the solid crystal. The mother liquid from crystallizer also has a certain degree of supersaturation, which need to be pumped into the thickener to eliminate supersaturation and then enter centrifuge for solid-liquid separation.

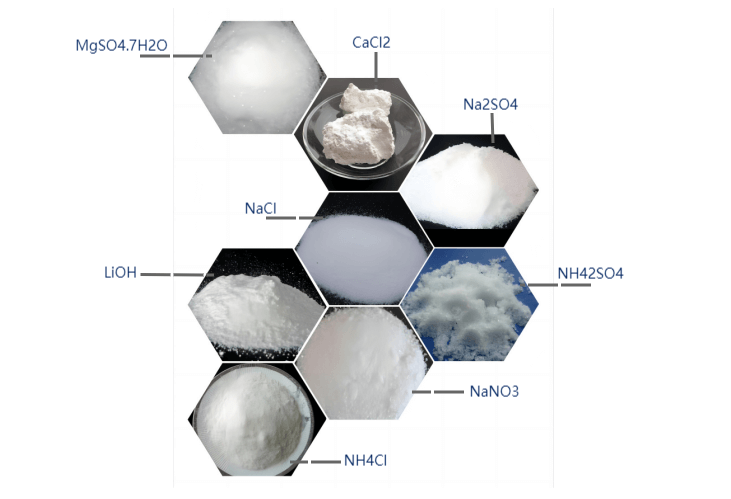

Classic Application for Freezing Crystallization/Separation System

- Separation and purifiation of liquid which including sodium sulfate and others.

- Separation the sodium and potassic.

- Crystallization of sodium sulfate in high COD waste water.

- Recover the by-product of sodium sulfate from the brine solution.

- Recover the valuable product in the Lithium Industry.

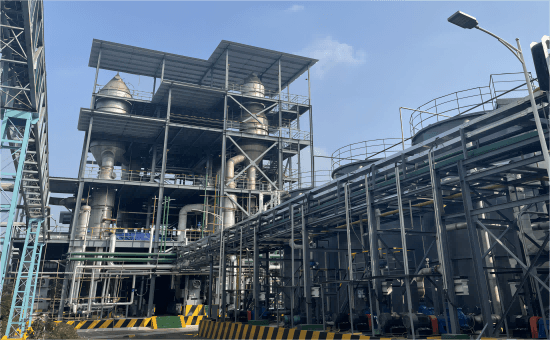

Special Engineering Design in Sanfeng Tech

- Steam compressor manufacturer

Sanfeng Tech brings the state-of-art technology, depth experience, and applications knowledge to industries, with 65 years of designing, production, and upgrading advanced manufacturer facility, including the mechanical vapor compressor solutions for any MVR Evaporator or Crystallizer application for Water Reuse, Concentration, Separation, Zero Liquid Discharge (ZLD), etc.

- Clearly 3D drawings

For corrective and effective design

For the installation and commissioning supervision

- Redesigned and Customized Automative Control System