Crystallizer

What is the crystallization process?

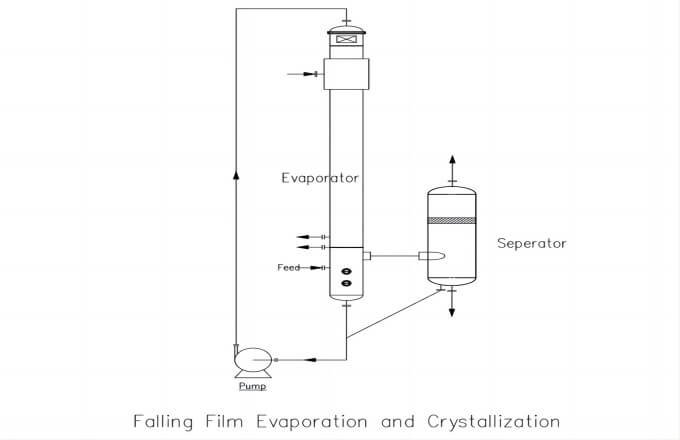

Evaporation crystallization is a crystallization process that removes a part of the solvent, mainly to make the solution evaporate and concentrate under normal pressure or reduced pressure to become a supersaturated solution.

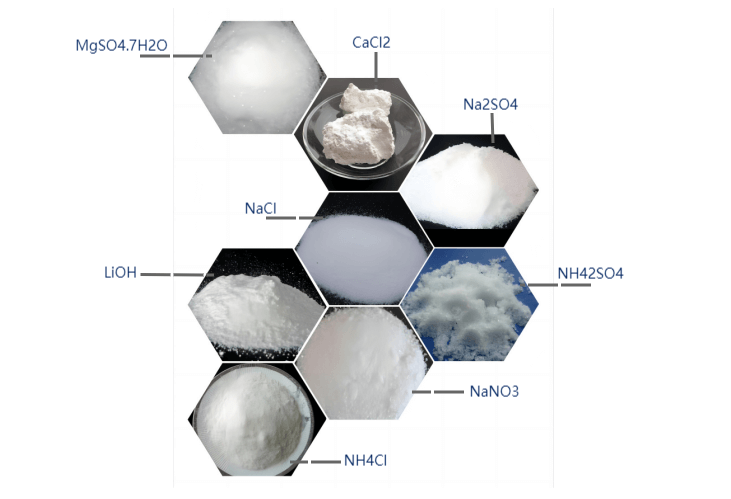

In the evaporation concentration and evaporation crystallization industry, these are commonly used:

- OSLO crystallizer

- DTB crystallizer

- FC type crystallizer

When doing the technology design for the ZLD Evaporation and Crystallization System to treat the wastewater, the suitable type of crystallizer is determined by:

- Feed Characteristic

- Final Treatment Requirement

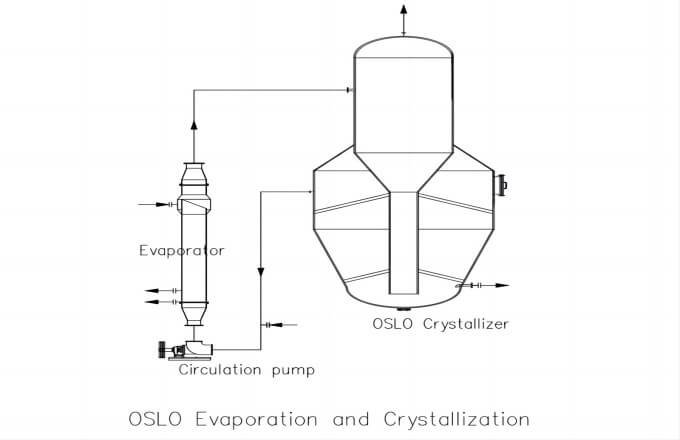

OSLO Crystallizer

The characteristics of the OSLO crystallizer are: the evaporation chamber and the crystallization chamber are connected by a central comedown, the body of the crystallization chamber has a certain taper, the lower section is smaller, and the upper section is larger. The supersaturated solution in the evaporation chamber flows to the bottom of the crystallization chamber through the central comedown and then flows upward. Due to the change of the flow channel cross-section, the liquid velocity distribution of the lower and the upper is formed, so that the crystal particles become liquidized with a graded size. bed. The crystal particles with larger particle size are enriched at the bottom of the crystallization chamber, and in contact with the solution with the highest degree of supersaturation flowing out of the comedown to make it grow larger so that large-particle crystals can be produced.

The OSLO crystallizer can be used to produce large-particle crystals.

DTB Crystallizer

The DTB type crystallizer has excellent performance and high production intensity. It can produce large crystal products with a particle size of 600-1200μm. It is not easy to crystallize in the device. It has become one of the most important forms of continuous crystallizer.

DTB crystallizer is the main type of crystallizer used in ZLD wastewater treatment.

The crystal particles are uniform and the size is moderate.

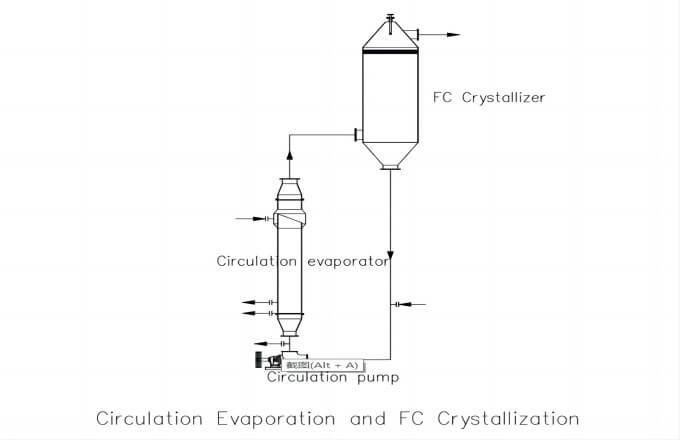

FC Type Crystallizer

FC type crystallizer is a forced external circulation type crystallizer that can be operated continuously. Part of the crystal slurry is discharged from the conical bottom of the crystallization chamber, is heated by the heat exchanger together with the raw material liquid through the circulation pipe, and returns to the crystallization chamber along the tangential direction. This kind of crystallizer is used in the crystallization process of indirect cooling method, evaporation method, and vacuum cooling method.

The production capacity of FC crystallizer is very large.

However, the average particle size of the is smaller and the particle size range is wider, not be widely used.