Steel and Power Plant

wastewater from steel and Power plant

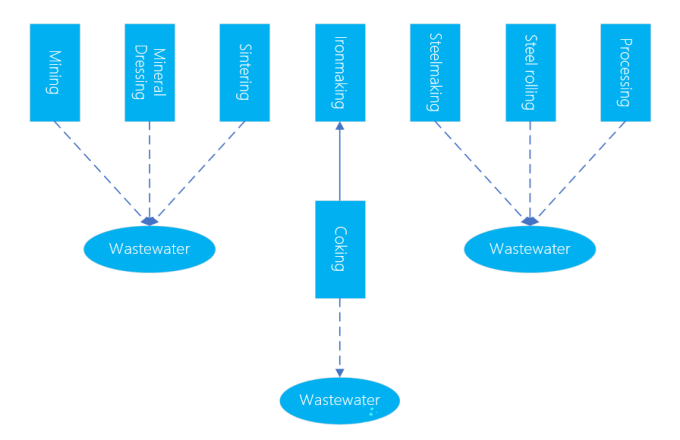

The wastewater includes process water, equipment and product cooling water, flue gas washing and site washing. Most waste water can be reused after simple treatment, and a small part of wastewater containing pollutants can be reused after special treatment.

Characteristics of steel wastewater:

- Water quality fluctuates greatly

- Large emissions

- High chroma, hardness and suspended solids content

- Low content of organic pollutants except coking wastewater.

Steel plant wastewater treatment technology

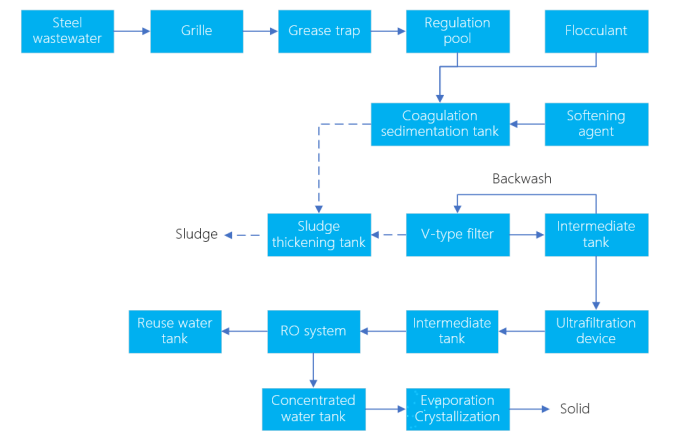

The treatment route of “coagulation sedimentation + V-type filter + ultrafiltration + reverse osmosis” is adopted, which can greatly reduce wastewater discharge. After reverse osmosis treatment, the TDS of the concentrated brine is generally not more than 8%, which can be reused. Although no wastewater is discharged from the plant, it is not really zero discharge.

To achieve zero discharge of wastewater from the steel plant, MVR or Multi-effect evaporation technology can be adopted, the concentrated brine after reverse osmosis is further concentrated and crystallized, the salt in the wastewater is solidified, and the distilled water is returned to the plant.

Technical advancement

By using low-grade steam in the steel plant or consuming a certain amount of electrical energy, the original treatment system reverse osmosis concentrated water is further evaporated into solid salt, which completes the original water treatment system and realizes zero discharge of wastewater from the steel plant.

Typical Cases

Case 1:

Evaporation Concentration to treat the desulfurization effluent in the steel and power plant

Case 2:

ZLD Evaporation Crystallization and Freezing Crystallization in the steel and power plant

Capacity: 80 T/H