Oil and Gas Wastewater

Oil and gas wastewater characteristics

Oil and gas wastewater usually has complex composition and more impurities. Therefore, it is necessary to design a suitable process according to the characteristics of water quality, and finally reach the standard to discharge.

Wastewater characteristics:

- The composition is complicated, and the water quality and quantity fluctuate greatly–it makes the pretreatment difficult.

- High fouling ion content–Evaporation concentration is easy to foul, and the pretreatment operation cost is high.

- Difficulty in disposing of crystalline salt–the salt composition fluctuates greatly and it is difficult to recycle salt.

Treatment process

Due to its serious pollution, the oil and gas wastewater is generally treated with multiple treatment processes. It is mainly divided into 3 steps:

- Pretreatment

- Evaporation concentration

- Evaporation crystallization

Pretreatment process

Pretreatment technology generally refers to a combination of coagulation and clarification and acid-base neutralization technology to remove suspended particulates, heavy metal ions and some salts in desulfurization wastewater.

For example, by increasing the pH, the heavy metal ions and hydroxide ions in the wastewater form a precipitate. The flocculation process refers to the use of PAC solution to solidify the small crystals precipitated in wastewater, making it easier to precipitate. The selection of PAC solution is very important, and it must be accurately treated according to the wastewater treatment process. If necessary, a coagulant can be used to make crystals precipitate more quickly. The clarification process is the final treatment method. The wastewater after the above treatment is put into the clarification equipment to separate the solid and liquid in the wastewater.

Evaporation concentration process

After the oil and gas wastewater is pretreated, suspended particles and heavy metal ions in the solution are removed. The content of Ca2+ and Mg2+ is still high, and entering the evaporation and concentration section can easily cause blockage of the heating pipeline. Ion exchange softening + reverse osmosis treatment technology is more commonly used to remove calcium and magnesium ions before evaporation, while achieving concentration of desulfurization wastewater. But the running cost of resin and film is higher.

Sanfeng can provide a more efficient and economical seeding method MVR falling film evaporation, with good effluent quality and strong resistance to load impact.

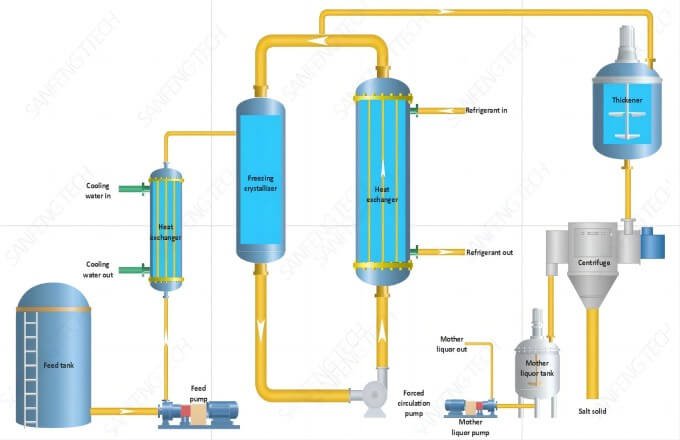

Evaporation crystallization process

At present, there are two main crystallization processes: Salt crystallization by seed method and MVR crystallization by nanofiltration. After comparing operating costs, salt concentration and quality, and ease of operation, the seed crystal method is more suitable for salt crystallization.

Advantages of MVR falling film evaporation

- No need to remove hard — low cost of medicine.

- High flow rate of liquid film in the tube layer + seeding method — long cleaning cycle.

- The technology is mature and reliable — Many successful cases at home and abroad.

- Vast evaporation area + turbulent liquid film — high heat transfer coefficient, remarkable energy saving effect.