Food Industry

Application for evaporators in food industry

Applications for evaporators in the food and beverage industry are mainly divided into two parts:

- Concentration and Crystallization:

Juice concentration, milk concentration, coffee concentration, fermentation product concentration, and traditional Chinese medicine extract concentration.

- Treatment of by-products in the process:

concentration of corn steep liquor, concentration of palm fruit squeezed liquid, concentration of pickle liquid, concentration of alcohol mash, etc.

Multi-effect evaporator, Falling film evaporator, Forced circulation evaporator, MVR evaporator, Crystallizer, etc. are widely used in the applications.

Working Principle of the Evaporation System

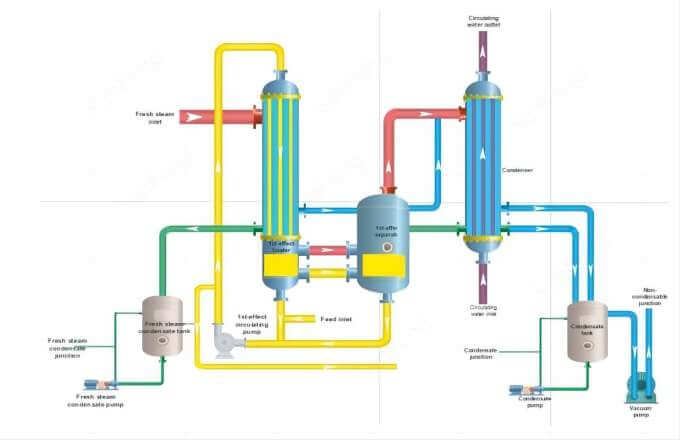

In most applications, falling film evaporators are selected as the processing equipment. According to different design requirements, the corresponding evaporation system will be designed. Energy-saving technologies such as TVR, MVR, and waste heat evaporation are also widely used.

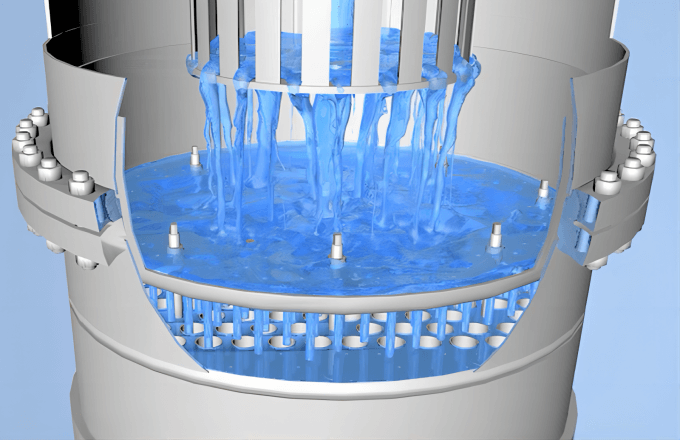

Various materials are added from the upper tube box of the falling film evaporator heater, and are evenly distributed through the liquid distribution and film forming device and enter each heating tube. Under the action of gravity, vacuum induction and air flow, they form a uniform film from the top to down flow. During the flow process, the material is heated and vaporized by the shell heating medium, and the generated steam and liquid phase enter the separation chamber of the evaporator together, and the vapor and liquid are fully separated. The steam enters the condenser for condensation (single-effect) or enters the next-effect evaporator as the heating medium, thus realizing multi-effect operation. The liquid phase is discharged from the bottom of the separation chamber or enters the next effect for subsequent heating and concentration.

Composition of the Evaporation System in the Food and Beverage Industry

- Evaporative heat exchanger

- Evaporative separator

- Evaporative circulating pump

- Condenser

- Vacuum pump

- Control system

Features of the Evaporation System in Food and Beverage Industry

- Falling film evaporator can evaporate materials with higher concentration and higher viscosity.

- Heat transfer efficiency is high.

- Short residence time, not easy to cause material deterioration, suitable for processing heat-sensitive materials.

- Small liquid hold-up, and the falling film evaporator can operate quickly according to changes in energy supply, vacuum, feed volume, concentration, etc.

- Low temperature difference evaporation can be used.

- Suitable for evaporating and concentrating foaming materials.