Anti-scaling innovation solution for FGD effluent evaporation

FGD effluent treatment

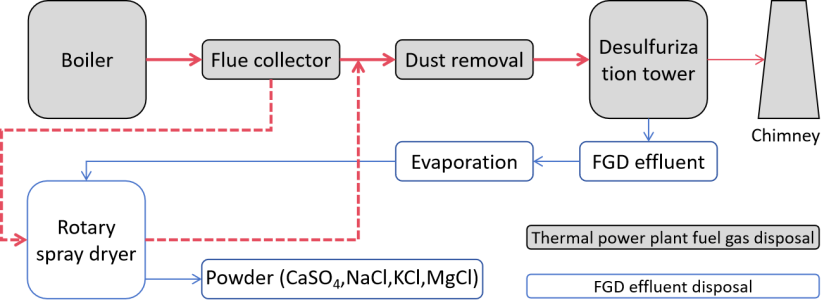

As an important utility facility, thermal power plants not only serve society’s demand for electricity but also lead to several serious issues haunting the environment such as acid rain, atmospheric contamination, and water pollution.

To prevent acid rain, the sulfate must be removed from the boiler exhaust gas through the desulfurization tower. During the process, FGD effluent is collected from the hydro-cyclone, dehydrator, etc. Then evaporation and concentration are adopted for salt extraction, after that the remains can be discharged without pollution.

Scaling problem

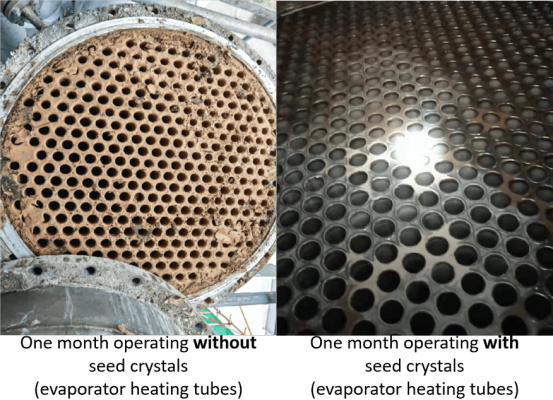

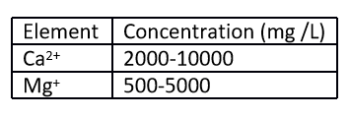

A major challenge in FGD effluent evaporation is scaling, primarily caused by the high calcium(Ca2+) & magnesium(Mg+) ion concentration.

During evaporation, the effluent concentration results in the supersaturation of Ca2+ and SO42-, leading to the precipitation of CaSO4 compound. The precipitated calcium sulfate(CaSO4) always causes a block in the heating pipes. Thanks to its stable crystal structure, both acid and alkali wash is not able to overcome this problem.

Just as we encountered in one of our projects, assuming the feed features a very small concentration of sulfate, the power plant operated the FGD evaporation system without adding any scale inhibitor. However, after just 1 month of operation, the heating pipes were totally blocked by the precipitated crystals, significantly affecting system performance and requiring costly maintenance.

Seed crystal method

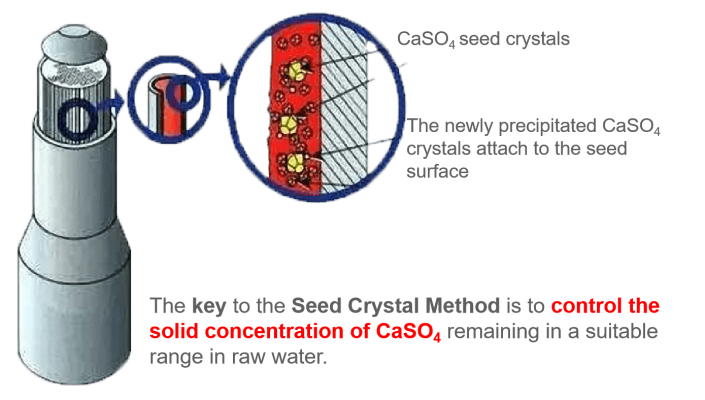

To overcome scaling challenges, Sanfeng carries out an innovative solution-seed crystal method, providing both effective anti-scaling and significant cost reductions.

Traditionally, to solve the scaling problem, chemical dosages are adopted as the pretreatment to remove the Calcium(Ca2+) & Magnesium(Mg+) ions before evaporation.

Innovatively, based on the high Calcium(Ca2+) & magnesium(Mg+) ion concentration feature, Sanfeng introduces the seed crystal(saturated CaSO4 solution) as an alternative anti-scaling solution.

The seed crystals feature the same crystalline surface and affinity with the newly precipitated CaSO4 molecules, having good effects on pollution absorption. Without additional dosage consumption, the evaporation process successfully realizes not only anti-scaling but also operation cost reduction.

Project case

With extensive experience in FGD effluent evaporation projects, Sanfeng has refined its process designs to maximize efficiency and reliability.

One notable project involved treating FGD effluent from a thermal power plant using a triple-effect forced circulation evaporation system. This system successfully operated for over 168 hours during commissioning and has now been running for over two years without major malfunctions.

The project delivered significant benefits to the plant owner:

- Reduced operation costs – No additional chemical anti-scaling agents required

- Lower maintenance costs– Fewer maintenance and flushing tasks

- Optimized energy consumption– Higher evaporation efficiency

- Enhanced resource recovery– Increased valuable salt recovery rate

Though it is a long crusade. To find the ultimate solution for the disposal of thermal power plant waste, Sanfeng never stops the step searching for innovation and learning project lessons.