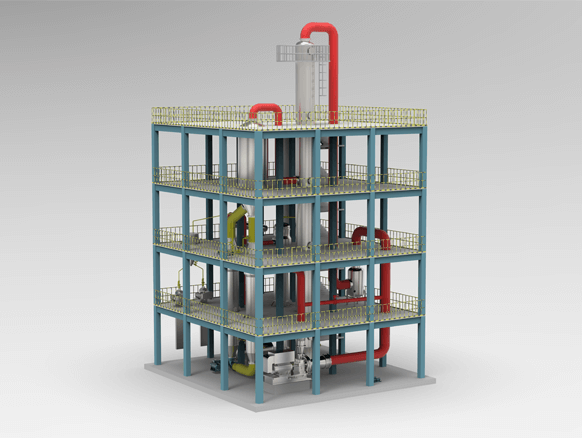

Anti-scaling and descaling have always been important technical problems in the operation of evaporative crystallization.

The fouling is mainly manifested in the fouling of the crystallizer and heating tube of the main equipment, which will not only reduce the effective volume of the equipment but also reduce the heat transfer coefficient of the heating tube, deteriorate production conditions and decrease production capacity.

Sometimes serious scaling will force production to stop, shorten effective production time, reduce equipment life and even damage equipment, and increase the consumption of raw materials and energy.

Ways to prevent scaling

In order to prevent scaling of evaporation equipment, these measures can be adopted:

① Pay attention to the material selection of evaporation equipment

② Polish the equipment pipeline

③ Pretreatment of evaporator inlet water

④ Reasonable circulating flow rate design

Method of descaling

In the process of system operation, based on years of research and production practice experience, we have summarized the following effective descaling methods:

① Water solution method

② Pickling method

③ Alkaline washing method

④ Mechanical descaling

⑤ High-pressure water cleaning technology